|

|||

|

Page Title:

Table II. Hardness requirements. |

|

||

| ||||||||||

|

|  MIL-A-12560H (MR)

w/INT. AMENDMENT 4

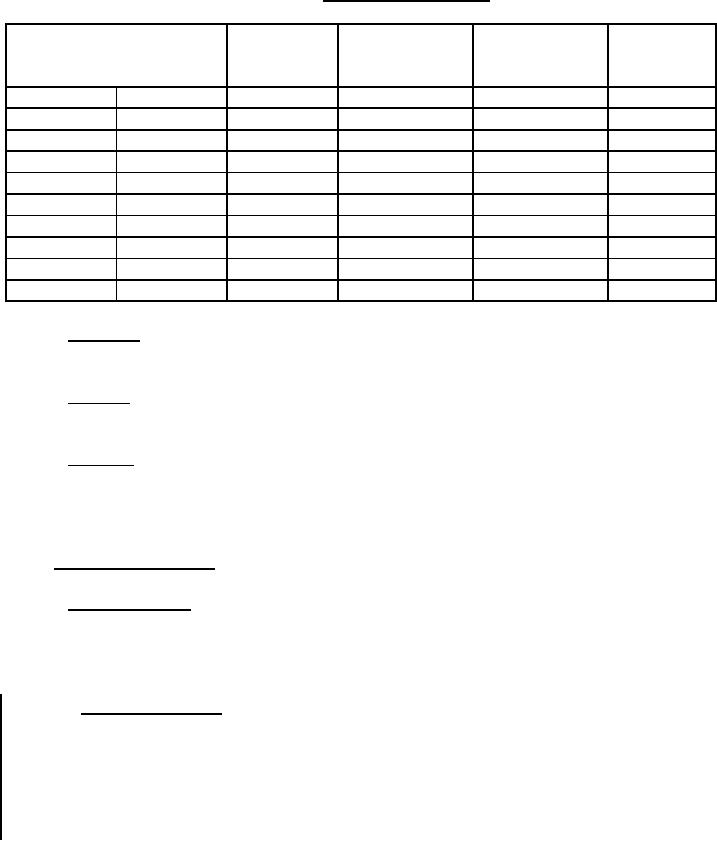

Plates shall not be stress relieved in a temperature range of 600-800 F. After stress relieving, the

plates shall be tested for hardness and shall meet the requirements of table II.

TABLE II. Hardness requirements.

Specified nominal thickness

Brinell hardness

Brinell

Rockwell C

of plate, inches

range, BHN,

indentation

hardness

From

To and incl.

Armor class

3000 kg load

diameters, mm

range, HRC

0.250

0.499

1&3

341-388

3.30-3.10

36.6-41.8

0.500

0.749

1&3

331-375

3.35-3.15

35.4-40.5

0.750

1.249

1&3

321-375

3.40-3.15

34.3-40.5

1.250

1.990

1&3

293-331

3.55-3.35

30.9-35.4

2.000

3.990

1&3

269-311

3.70-3.45

27.7-33.0

4.000

6.000

1&3

241-277

3.90-3.65

22.7-28.7

6.001

6999

3

241-277

3.90-3.65

22.7-28.7

7.000

8.999

3

223-262

4.05-3.75

19.2-26.7

9.000

12.000

3

212-248

4.15-3.85

16.4-24.2

0.250

1.250

2

277-321

3.65-3.40

28.7-34.3

3.2.4.2 Repairing. Unless otherwise approved by the procuring activity, weld repairs shall not be

made on any plates.

3.2.4.3 Forming. Forming after the final quenching and tempering operations shall not be done

except when authorized by the procuring activity.

3.2.4.4 Grinding. Grinding is not required but shall be performed to remove minor defects not

affecting the serviceability of the material provided that, unless otherwise authorized by the

procuring activity, the grinding does not result in the reduction of the plate thickness in the

ground area to less than the tolerances specified in tables III, IV, or V as applicable.

3.2.5 Mechanical properties.

3.2.5.1 Surface hardness. The average surface hardness of each plate including first article

samples shall be within the Brinell hardness range shown in table II for the applicable class and

thickness. The diameters of Brinell hardness impressions on any individual plate shall not vary

by more than 0.15 mm.

3.2.5.1.1 Class 4 armor plate. Surface hardness is required on every plate to insure quality and

uniformity of product. In addition, first article samples shall be tested for through hardness to

verify that they are within the HB range specified in 1.2.5 and 1.2.6. Respective diameters of the

Brinell hardness impression taken on an individual plate shall not vary by more than 0.15 mm.

Each lot shall be tested for through hardness. Acceptance for Class 4a material requires a

minimum through hardness of HRc 47 (BHN 442). Acceptance for class 4b material requires a

maximum through hardness HRc 41 (BHN 381).

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |