|

|||

|

|

|||

| ||||||||||

|

|  MIL-A-12560H (MR)

w/INT. AMENDMENT 4

3.2.8 Identification marking. Identification marking and records shall be such as to ensure

positive identification of all plates, including test samples and specimens, with the lot and

corresponding heat from which they were produced. First article and acceptance ballistic test

plates shall also be marked with the manufacture's name or trademark, the number of this

specification, and the ordered plate thickness in inches. First article plates shall be marked

"PRE," acceptance plates "ACC," and retest plates shall be marked "R1" and "R2." If a second

set of retest plates are submitted they shall be marked "RR1" and "RR2." The marking shall be

approximately 1/16 inch deep and approximately 1/2 inch high and located along the edge with

the lifting hole, if present, and shall be stamped into the surface unless the plate hardness makes

painting necessary. All plate markings shall be highlighted with a highly visible yellow or orange

border such as fluorescent paint or highlighted with a special white paint intended to delineate

and highlight stamping. The primary plate rolling direction shall be identified. Manufacturers

supplying armor, to be used for proving ground testing of ammunition, are required to:

a. Mark each class 3 plate with one foot square blocks showing thickness at the center

of each block. The acceptance of each plate shall be based on these measurements

meeting the thickness requirements set forth in table V.

b. Stamp each plate "HOMO, class 3, MIL-A-12560, plate No. ____, heat No.____."

Stamping shall be approximately 1/2 inch high letters to a depth approximately

1/16 inch. Location of stamping for all plates shall be in the upper right hand corner.

3.2.9 Information required. A statement showing the product analysis of each melt and complete

details of the heat treatment of each lot shall be furnished for the files of the procuring activity.

All elements of the chemical composition shall be shown in the statement, including special

additives or hardening agents, whether shown in table I or not.

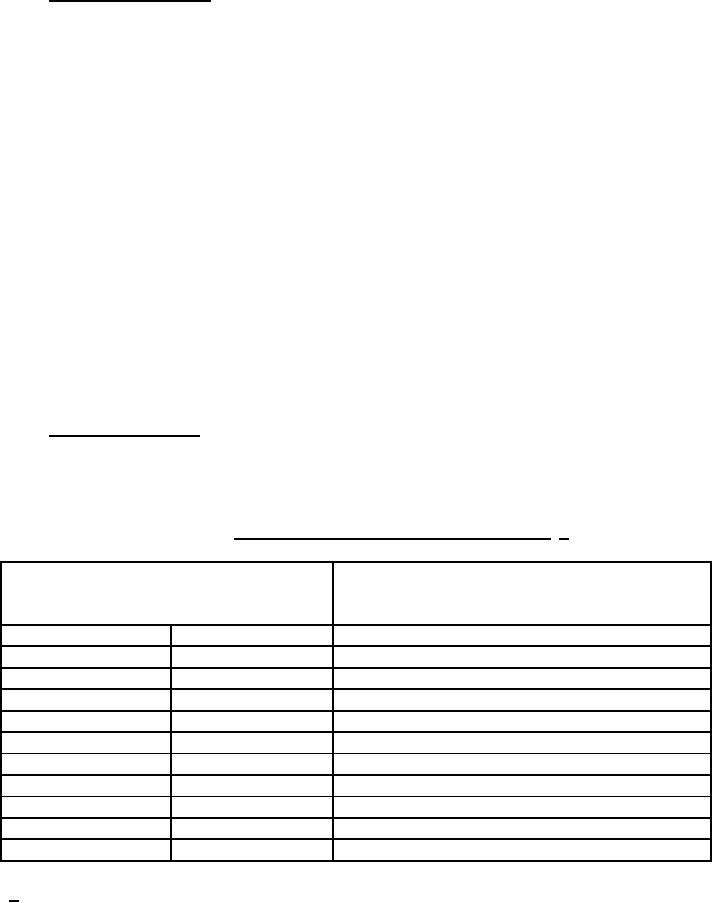

TABLE V. Thickness tolerances for class 3 armor plate. 1/

Specified plate thickness,

Permissible variation

inches

plus or minus,

Over

To and including

inches

0.250

0.500

0.015

0.500

1.125

0.020

1.125

1.499

0.025

1.499

1.749

0.030

1.749

1.999

0.035

1.999

2.999

.0.040

2.999

4.000

0.045

4.000

6.000

0.075

6.000

8.000

0.083

8.000

10.000

0.098

10.000

12.000

0.122

1/ This armor is not intended for use in combat vehicles. To obtain these thickness tolerances

special surfacing finishing shall be required.

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |