|

|||

|

Page Title:

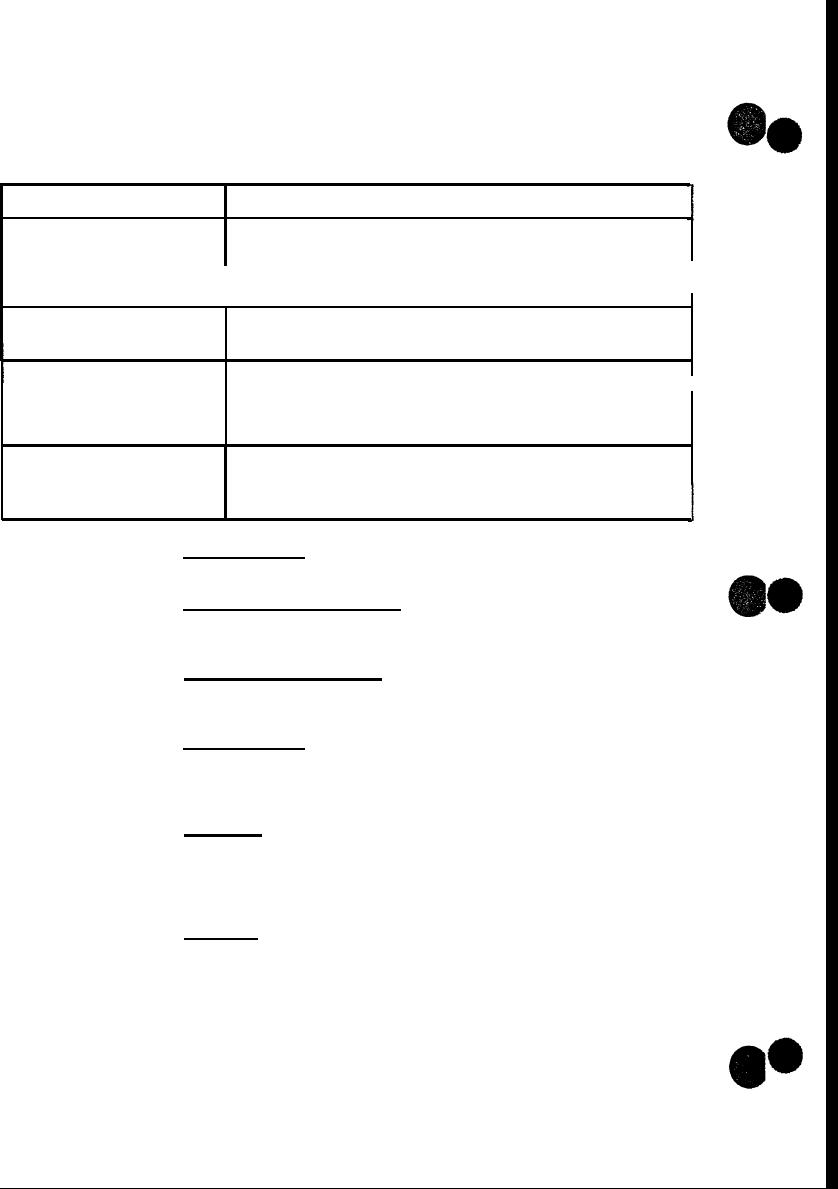

Table III. Classification of Defects for Preparation for Delivery |

|

||

| ||||||||||

|

|  MIL-A-21165A

TABLE III

CLASSIFICATION OF DEFECTS FOR PREPARATION FOR DELIVERY

Item

Defects

Exterior and

Missing, incorrect} incomplete, illegible, of

interior markings

improper size, location } sequence or method of

application; marking not the same on interior

and exterior containers.

Packaging and

Any non-conforming component; any component miss-

packing materials

ing, damaged or otherwise defective.

Workmanship

Inadequate application of components such as in-

complete closure of the unit package, intermediate

package, container flaps, or loose strappings,

etc., bulging or distortion of the container.

,

Number per container is more or less than re-

Exterior and interior

quired; gross or net weight exceeds the require-

weight or content

ment.

4.5.2

Strength tests - Each sample adapter shall be subjected

to the following strength tests and shall meet the requirements of 3.4.1.

4.5* 2.1

Static horizontal loading - Apply a load of 2300 pounds

to a collared adapter parallel to the base of the adapter, as shown in

Figure 1.

4.5.2.2

Static vertical loading - Apply a load of 5475 pounds

to a collared adapter through the longitudinal axis of the adapter, as

shown in Figure 1.

Impact. loading - A force of 5950 pounds resulting from

4.5.2.3

impact loading shall be applied to the adapter at an angle of 22-1/2 degrees

as shown in Figure 1. The impact loading shall be applied as a half-sine

wave with a base of 0.050 seconds and a peak of 5950 pounds.

Vibration - Each sample adapter shall be fastened and

4*5* 3

vertically tensioned to 200 pounds and vibrated in this condition on a

vibration table at a double amplitude of 1/16 inch at 60 cycles per second

for a period of 6 hours. The adapter shall meet the requirements of 3.4.2.

The endurance test shall be conducted after the completion of this test.

4.5.4

Endurance - The sample adapter which has been subjected

to the vibration test, shall be subjected to 1000 cycles of engaging and

disengaging, The adapter shall meet the requirements of 3.4.3.

8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |