|

|||

|

|

|||

| ||||||||||

|

|  MIL-B-45390A(AT)

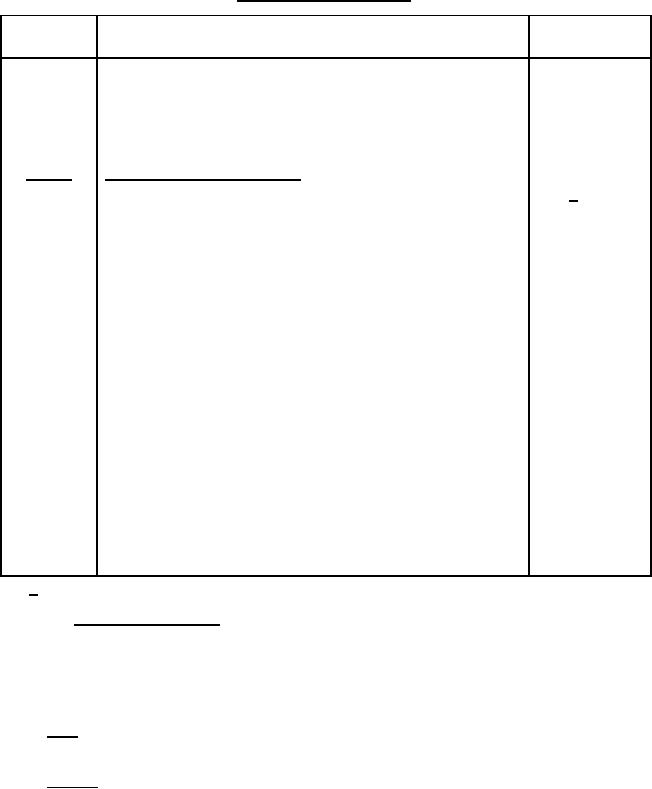

TABLE III. Classification of defects Continued.

Method of

Category

Defect

examination

109

Faulty workmanship affecting performance (see 3.7).

Visual and

Functional

110

Clutch, switch, lamp, circuit breaker, and leads; improper Visual and

assembly, damaged, or inoperative.

Functional

Minor

AQL 150 defects/100 units

201

Dimensions not affecting interchangeability, not within

SIE 1/

tolerance (see 3.3).

202

Identification marking, improper (see 3.3 and 3.5).

Visual

203

Technical literature; missing or incomplete (see 3.3.3).

Visual

204

Right angle drive, pump and coupling; improper

Visual and

installation or leaks.

Functional

205

Front mounting brackets and moldboard; improper

Visual

adjustment.

206

Control assembly and guards; improper installation.

Visual and

Functional

207

Hydraulic cylinders, reservoir, filter, hoses, pipes, and

Visual and

guards; improper installation, incorrect fluid level or

Functional

type.

208

Finish; improper coverage, application, or materials

Visual

(see 3.6).

209

Faulty workmanship affecting appearance (see 3.7 and

Visual

4.5.2.2.1).

210

Clutch, switch, lamp, circuit breaker, and leads; improper

Visual and

installation.

Functional

1/ SIE = Standard Inspection Equipment.

4.5.2.2.1 Unclassified defects. All defects that have no effect on function, safety,

interchangeability or life, but are considered departures from good workmanship will be noted in

writing. Workmanship deficiencies falling within this category and recurring in five consecutive

lots, or ten lots or more within a 30-day period will be added to the minor defects classification

with no increase in AQLs.

4.5.3 Test. One bulldozer kit from each 50 bulldozer kits shall be subjected to the tests

specified in table II.

4.5.4 Failure. Failure of any bulldozer kit to pass any of the specified inspections shall be

cause for the Government to refuse acceptance of the production quantity represented, until

action taken by the contractor to correct defects and prevent recurrence has been approved by the

Government.

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |