|

|||

|

|

|||

|

Page Title:

|

|

||

| ||||||||||

|

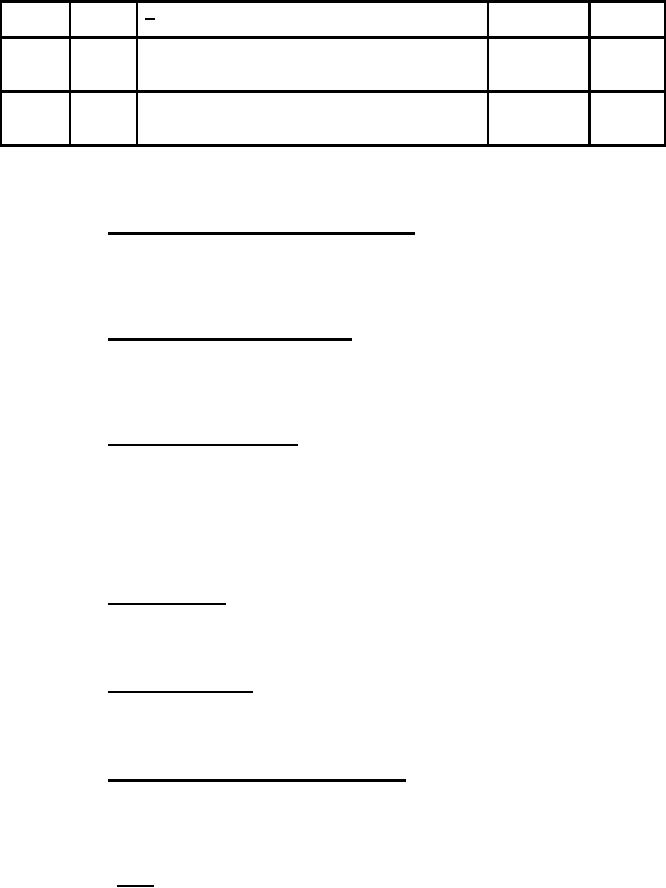

|  MIL-B-52734C (ME)

4.5.2.12

3.7

X

X

1/ post-test hydraulic cleanliness

-

-

Reliability and maintainability

4.5.2.13

3.16

and

3.17

-

-

Slinging and tiedown provisions

4.5.2.14

3.18

and

and

4.5.2.15

3.19

1/

Applies to type II bridge bays only.

2/

Applies to type I bridge bays only.

4.5.2.3 Limbering up of hydraulic cylinder. Prior to subjecting the

cylinder to the tests specified herein, the cylinder shall be cycled through

25 complete cycles. One cycle shall consist of extension and retraction of

the rod through full travel without bottoming. The cycling shall be done by

either hydraulic pressure or mechanical means.

4.5.2.4 Hydraulic cylinder pressure. Place the cylinder in the test frame

(see 3.13) so that the piston is restrained from bearing against either

cylinder head. In accordance with drawing D13218E4078, note 5, subject Port

"A" of the cylinder to 9700 psi, plus zero psi minus 200 psi, for 5 minutes.

Nonconformance to 3.5.1 shall constitute failure of this test.

4.5.2.5 Cylinder relief valve. The hydraulic cylinder shall be pressurized

until the relief valve opens. Do not pressurize the cylinder above 9700 psi.

Opening of the valve at any pressure below 9500 psi or failure to open before

9700 psi is reached shall constitute failure of this test. After passing the

above test, the pressure shall be reduced to 7000 psi. Failure of the valve

to close (as indicated by an internal leakage of no more than 50 drops a

minute at Fort "B") before 7000 psi is reached or nonconformance to 3.5.6

shall constitute failure of this test.

4.5.2.6 Control valve. The hydraulic pump control valve shall be subjected

to a pressure between 9700 psi and 9900 psi. Evidence of leakage or permanent

deformation of the valve or nonconformance to 3.5.5 shall constitute failure

of this test.

4.5.2.7 Internal leakage. During the hydraulic cylinder pressure test,

leakage shall be measured at Ports "A" and "B", as specified on drawing

D13218E4078 of top assembly drawing TA13218E4005. Leakage in excess of the

rate specified on D13218E4078 shall constitute failure of this test.

4.5.2.8 Ramp articulation system Pressure. Subject the hydraulic pump,

hose and hydraulic cylinder (Ports "A" and "B.") assembly to a pressure

between 1500 psi and 1600 psi for least 1 minute. Evidence of external

leakage, permanent deformation or nonconformance to 3.5.2, 3.5.3 or 3.5.4

shall constitute failure of this test.

4.5.2.9

Pull. Install the interior roadway ponton in the test frame (see

3.13) and apply a tensile load at each end through the ponton eye and yoke

(see drawing D13218E4003 (finds 16 and l7) of top assembly drawing,

TA13218E4002). Apply the tensile load through a ramp hydraulic cylinder

(see 3.13) pressurized in increments of approximately 925 psi to a pressure of

16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |