|

|||

|

Page Title:

Table VIII. Sample size for group A, subgroup 1 |

|

||

| ||||||||||

|

|  MIL-C-18312F

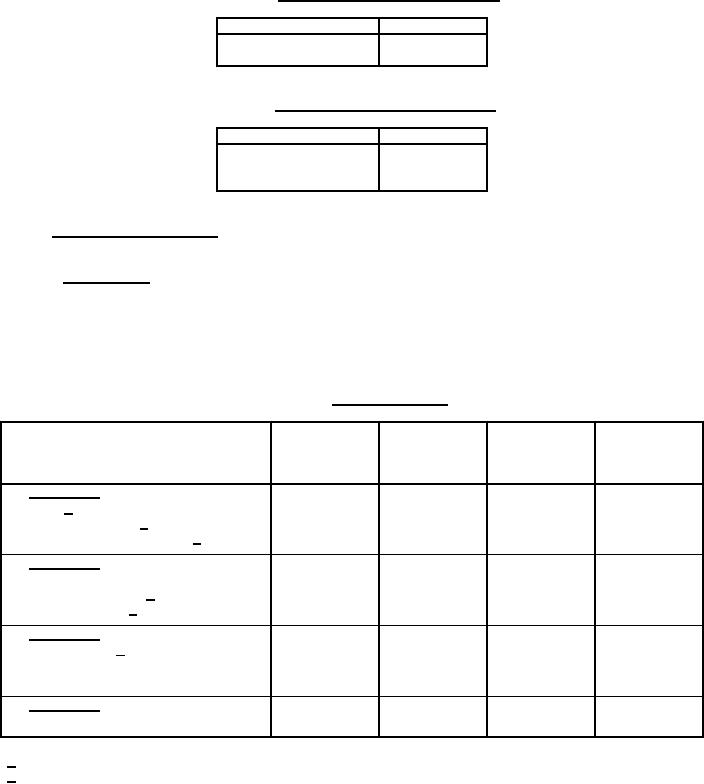

TABLE VIII. Sample size for group A, subgroup 1.

Lot size

Sample size

1 - 125

100%

126 - Up

125

TABLE IX. Sample size for group A, subgroup 3.

Lot size

Sample size

1 - 90

3

91 - 500

13

501 - Up

20

4.6.2 Periodic group B inspection. Group B inspection shall consist of the examinations and tests specified in

table X in the order shown.

4.6.2.1 Sampling plan. Group B inspection shall be performed once every 2 months on samples from each

inspection lot (see 4.6.1.1). A sample, consisting of twelve specimens of voltage ratings representing a fair cross-

section of the lot and of the highest watt-second rating in each voltage category, shall be selected for each of

subgroups 1, 2, and 3 at random from each lot. Every 12 months, 12 sample capacitors that have completed the

group A life test, shall be subjected to the extended life test of subgroup 4, in accordance with 4.7.16.3. Shipments

of lots shall not be delayed pending results of the life test, except as specified in 4.6.2.3. Not more than one

defective capacitor will be allowed for a single sample (12 specimens).

TABLE X. Group B inspection.

Number of

Number of

defects

sample units to

Examination or test

Requirement

Method

permitted

be inspected

paragraph

paragraph

Subgroup 1

Vibration 1/

3.11

4.7.8

Salt spray (corrosion) 2/

3.12

4.7.9

12

1

Thermal shock and immersion 2/

3.13

4.7.10

Subgroup 2

Solderability (axial wire leads only)

3.14

4.7.11

Shock, specified pulse 1/

3.15

4.7.12

12

1

Moisture resistance 2/

3.16

4.7.13

Subgroup 3

Terminal strength 2/

3.17

4.7.14

Low temperature and capacitance change

12

1

with temperature

3.18

4.7.15

Subgroup 4

Life (extended)

3.19

4.7.16.3

12

1

1/ The time period for shock and vibration tests is a minimum of once every 24 months.

2/ If the manufacturer can demonstrate that this test has been performed five consecutive times with zero failure,

this test, with the approval of the qualifying activity, can be deleted. The manufacturer, however, shall perform

this test every 3 years after the deletion as part of long term design verification. If the design, material,

construction processing of the part is changed, or if there are any quality problems, the qualifying activity may

require resumption of the specified testing. Deletion of testing does not relieve the manufacturer from meeting

the test requirements in case of dispute.

11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |