|

|||

|

|

|||

| ||||||||||

|

|  MIL-C-63550E(AR)

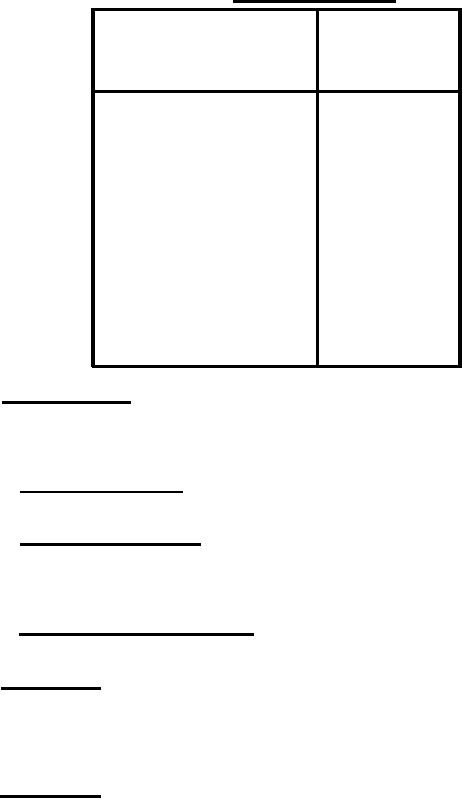

Adapter nut torque.

TABLE I.

Torque

required

Shell size

(in/lb)

08

35/40

10

40/45

12

50/55

14

65/75

16

65/75

18

80/85

20

90/95

22

100/110

24

120/130

130/140

28

32

150/160

36

175/185

40

190/200

3.3.3 Cable markings. Markings identified in 3.3.3.2 shall be applied on

sleeving conforming to MIL-I-23053/5 or equivalent by typing with black char-

acter. The marking shall be arranged and located in accordance with the

cable assembly drawing.

3.3.3.1 Marking protection. All marking shall be covered with clear

sleeving conforming to MIL-I-23053/8, or equivalent.

3.3.3.2 Cable identification. Each cable shall be identified in accordance

with MIL-STD-130. The marking shall include the design activity FSCM, the

abbreviation ASSY, the part number, the manufacturer's FSCM and the cable

reference designation.

3.3,3.3 Termination Identification. Each termination, connector, lug, etc.,

shall be identified with the applicable reference designation.

3.3.4 Age control. The assembly and earliest cure dates (in quarter and

year) of any synthetic age-sensitive elastomer installed within the cable

assembly shall be indelibly affixed to the cable assembly. All age-sensitive

elastomers shall be installed in the cable assembly within 8 quarters after

the cure date.

3.3.5 Workmanship. The assembly shall be in accordance with the workman-

ship requirements of MIL-STD-454, requirement 9.

18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |