|

|||

|

Page Title:

Table 1. Electrical system-cont. |

|

||

| ||||||||||

|

|  MIL-D-52916A(ME)

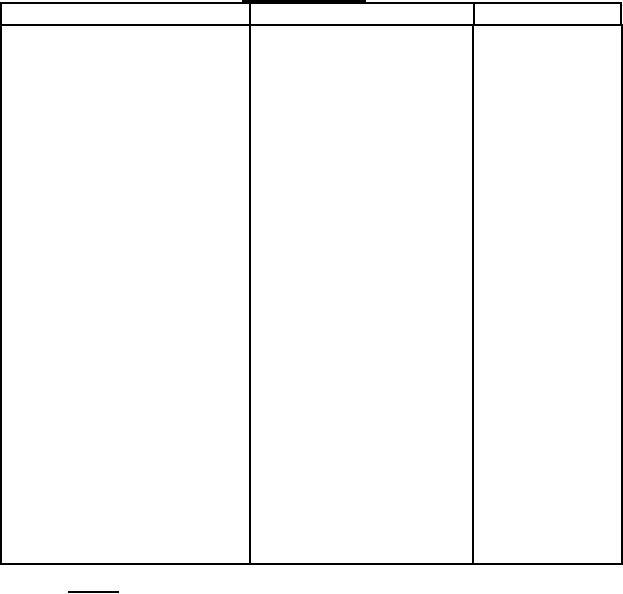

TABLE I. Electrical system - Continued.

Description

Requirement

Quantity

Blackout combination lamps,

Military type,

2 ea.

rear

MS51330

Reflectors

MS35387

8 ea., min.

Low tension cable

MIL-C-13486, 14

AR

A.W.G. Min.

Harness insulation

MIL-I-631 & MIL-I-15126

AR

AR

Loom

Semitrailer type

polyethylene tubing or oil

proof SAE J562 loom

Conduit

Commercial, thinwall type

AR

Cushioned support clamps

MS21322, MS21333,

AR

MS21334

Circuit number bands

MIL-B-43436 &

AR

MIL-B-43436/1

Friction connectors

MS 27142 through

AR

MS27148 & MS33800

waterproof

Connector lubricant

MIL-S-8660

AR

Connector holder clip

Plastic or spring clip,

AR

similar to MIL-C-24066 &

MIL-C-24066/2-329

Terminal connectors

Spade type per SAE J561

AR

with heat Shrinkable or

integral insulator sleeves

Hazard warning signal

DOT Regulations, SAE

1 assy

J910, and SAE J945

3.20.1 Wiring. The wiring for both the service and blackout light systems shall be in

accordance with the figure furnished by the contracting officer (see 3.26 and 6.4). The wiring

shall be protected from road splash. The wiring jacket shall not be fabricated from poly vinyl

chloride (PVC). Cushion clamps, loom, thinwall conduit and grommets shall be provided to

prevent whipping, chafing and other mechanical and heat damage. Wiring shall be fastened to

the frame at intervals not to exceed 3 feet (.9144 m). Two or more cables following the same

routing shall be enclosed in loom or conduit having each end waterproofed, or shall be bound

together in harness with 0.5 overlapping wraps of plastic tape. Splices shall be waterproofed.

Mechanical splicing devices , if used, shall be fastened to the frame members with the interior of

the device waterproofed with silicon sealant. All connections shall be varnished according to

MIL-V-173. All circuits shall be identified by number coding as specified in the Government

furnished diagrams (see 3.26 and 6.4). The circuit number bands shall be installed near each

connection. The mating surfaces of the elastomer friction connectors shall be sealed with silicon

sealant prior to assembly. The assembled friction connectors shall be secured to the frame with

12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |