|

|||

|

|

|||

| ||||||||||

|

|  MIL-E-22200G

(a) A 10 to 15 gram sample of electrode coatings shall be ground, well

mixed and a 0.35 gram sample weighed and placed in 250 mL beaker.

Add 15 mL concentrated hydrochloric acid to the beaker and heat

until action ceases, Add 5 mL concentrated nitric acid and heat

until action ceases. Add several drops of hydrofluoric acid and

heat until action ceases. Then add 15 mL concentrated perchloric

acid (70 percent) and heat until

fumes appear. Dilute to

100 mL with water, filter and wash with hot water, saving the

filtrate.

Ignite the filter paper and residue in a platinum

crucible,

(b) Fuse the ignited residue with sodium carbonate, cool and dissolve

in water. Acidify with hydrochloric acid. Heat the solution,

filter and combine the filtrate with the filtrate obtained above.

Add 2 mL of concentrated nitric acid and boil. Add 5 grams of

ammonium chloride or ammonium nitrate and macerated filter paper

to the solution and make ammoniacal with ammonium hydroxide. Boil

until iron hydroxide coagulates then filter and wash with 2

percent ammonium chloride or ammonium nitrate solution. Re-

dissolve the residue from the paper with warm 1.1 hydrochloric

acid and wash the paper thoroughly with hot water, Repeat the

ammoniacal precipitation and washing as above and discard the

filtrate.

Ignite the residue and filter paper in a platinum

crucible and fuse gently with sufficient potassium pyrosulfate

to dissolve all residue. Cool and leach the contents of

the crucible with approximately 100 mL of hot 5 percent sulfuric

acid solution. Remove the crucible and rinse with distilled

water. Upon cooling, pass the solution through a Jones reductor

into a receiving flask containing 15 mL of 0.1N ferric ammonium

sulfate solution. Titrate with 0.1N potassium permanganate.

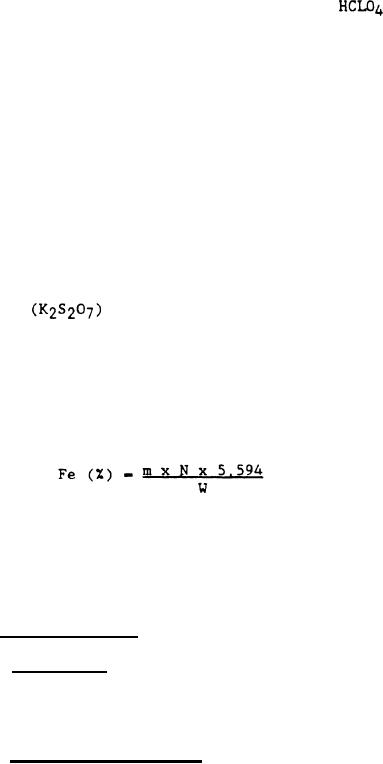

(c) Total iron content shall be determined in accordance with the

following equation:

Where:

m = mL potassium permanganate

N = Normality factor of permanganate

W = Weight of sample in grams

Fe = Total iron content

4.6.10

Alloy identity.

4.6.10.1 Procedure.

The alloy identity test method may include chemical

analysis, metal sorting devices, other approved methods, or a combination of

methods.

The test method shall be submitted for approval to NAVSEA, or the

agency concerned.

4.6.10.2 Acceptance criteria.

The material shall be of the type specified.

17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |