|

|||

|

Page Title:

Table I. Hazardous solvent content1/ |

|

||

| ||||||||||

|

|  MIL-E-24763A(SH)

w/INT. AMENDMENT 1

3.4.2. Crystalline silica content. When evaluated in accordance with 4.7 the coating of shall not contain

crystalline silica in excess of 0.1% by weight of the dry paint.

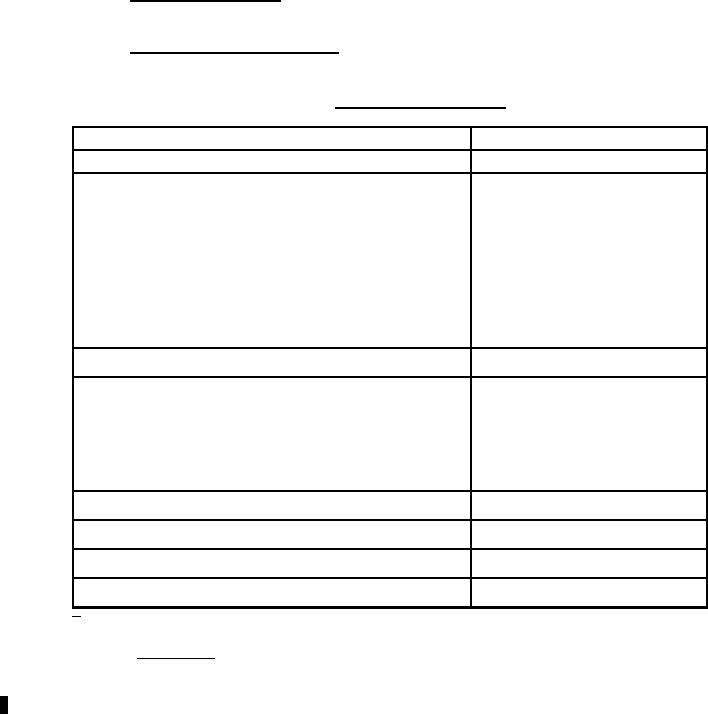

3.4.3. Hazardous air pollutants (HAPs). The contents of HAPs solvents in the total enamel shall be not

greater than the weight percent (%WT) values listed in table I when tested as specified in 4.6.14.3.

TABLE I. Hazardous solvent content1/

Hazardous solvent in total enamel

Maximum, %WT

Benzene

0.05

Chlorinated solvent(s), total

0.05

Carbon tetrachloride

Chloroform (trichloromethane)

Methylene chloride (dichloromethane)

Tetrachloroethylene (perchloroethylene)

1,1,1-Trichloroethylene (Methyl

chloroform)

Trichloroethylene

Ethyl benzene

0.05

Methyl, ethyl and butyl mono-ethers of

0.05

ethylene glycol or the acetates, total

(methyl, ethyl and butyl cellosolves

and acetates)

Methyl ethyl ketone (MEK)

0.05

Methyl isobutyl ketone (MIBK)

0.05

Toluene

0.05

Xylene (all forms), total

0.1

1/

By Data Certification

3.5. Composition. The contractor is given his choice in the formulation of the enamel provided the end

product conforms to all requirements of this document (see 4.7). However, the contractor shall assure

composition conforms to the requirements of 3.4 and that soluble metal content and total metal content of the

enamel shall be less than the values listed in Tables II and III when tested in accordance with 4.6.14.

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |