|

|||

|

|

|||

| ||||||||||

|

|  MIL-E-63300A(AR)

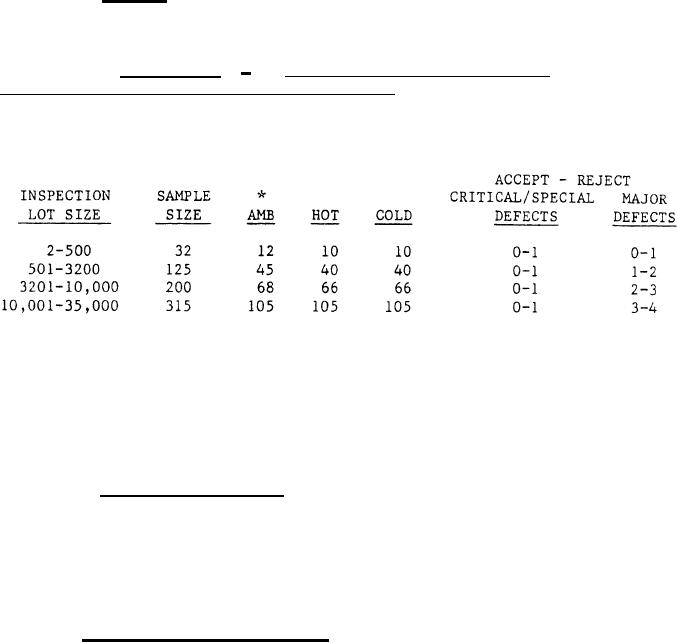

4.4.3 Testing. Testing is described in the First Article and

Quality Conformance Inspection "Classification of Defects and Test"

forms and as specified in 4.5.

4.4.3.1 Ambient (25C + 5C), Hot (63C + 3C) and Cold

(-37C - 3C) temperature functioning tests. The table below

shall be used for the selection of the lot acceptance sample sizes

for ambient, hot and cold temperature testing of lots of electronic

assemblies.

The units shall be tested for all the functional parameters

(under critical, special, major) listed in 4.4.2.5. Reject number

is the number of defective units that would reject the lot. since

all the units have to be 100% inspected at ambient for critical and

special defects the quantities listed under * do not have to be

reinspected for critical and special defects at ambient temperature

(see 4.5.16) but must be inspected for major defects.

4.4.4 Inspection equipment. The inspection equipment required

to perform the examinations and tests prescribed herein is described

in the `Paragraph Reference/Inspection Method' column in

Classification of Defects and Tests forms beginning with paragraph

4.4.2.1. The contractor shall submit for approval inspection

equipment designs in accordance with the terms of the contract. See

Section 6 of MIL-A-48078, and section 6.3 herein.

4.5 Test methods and procedures . Only government approved test

equipment and test fixtures shall be connected to electronic

assemblies under test to verify that it complies with the

requirements specified herein. Increasing the PTB oscillator

frequency to reduce test time is acceptable provided, the higher

frequency oscillator signal maintains an approximate 50% duty cycle

and has a peak amplitude frequency oscillator signal which does not

cause or mask malfunctions in the functional operation of the

electronic assembly; the higher frequency oscillator signal is well

within the capability of the test equipment to monitor PA, TL, SD

(normal or extended) with an accuracy of 3 PTB counts; the actual

34

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |