|

|||

|

Page Title:

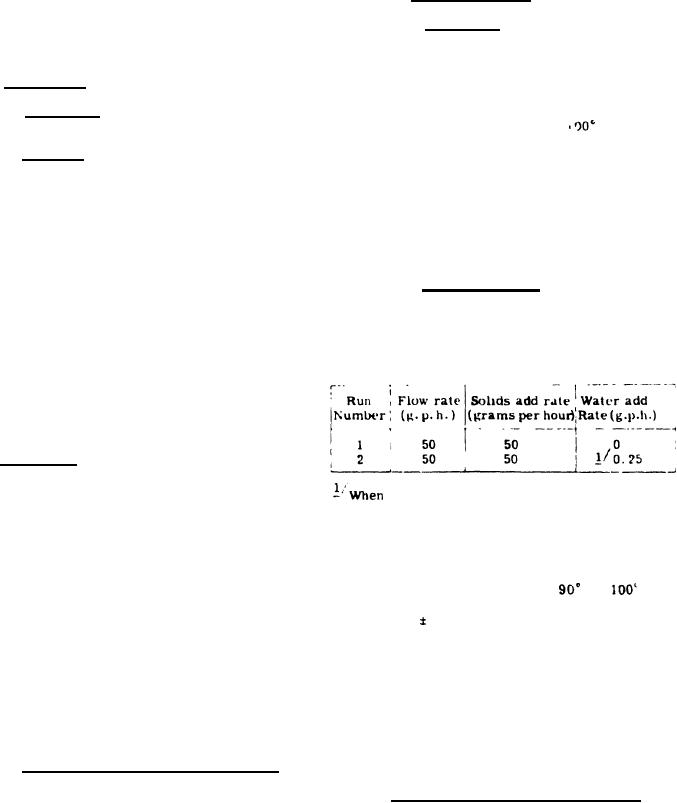

Table III - Filtering ability determination |

|

||

| ||||||||||

|

|  MIL-F-20627B

concerned. The method is, in general, the ASTM

(2) Filter pads, glass fiber, Number 934-

Committee D-2 "Proposed Method of Test for

AH Reeve Angel 2.4 centimeter discs

to fit a Number 4 crucible similar to

Particulate Matter in Hydrocarbons".

Fisher Scientific Company Catalogue

4.5.4.4 Test

procedures. -

Number 9-873.

(3) Tri-solvent composed of equal parts of

particle free benzene, acetone and

4.5.4.4.1 Flow rate. - Fuel shall be circu-

methanol.

lated through the test apparatus including the test

(4) Standard laboratory equipment for

filter case without elements until aanalysis of

filtering, drying and weighing.

effluent samples shows that the system contami-

(b) Preparation. - Preparation shall be as

nation is less than 1 milligram per liter. One

class 2 or two class 1 elements shall be installed

follows :

(1) Tri-solvent. - Render particle free by

in the test filter case. The cleaned diesel fuel at

filtering through a crucible containing

F. shall be

a temperature of between 90 and

two glass fiber pads.

circulated through the system at a constant rate

(2) Crucibles. - Wash with hot water and

of 50 g.p.h for a period of 30 minutes. One-

detergent, acid clean, rinse with

liter effluent samples shall be taken immediately

tap water followed by three rinsings

after the flow rate has been established, at 5

with distilled water and dry. Place

minutes, 10 minutes, and at 30 minutes. Circu-

two filter pads in the crucible and cen-

lation of the fuel shall be continued at flow rates

ter by tapping crucible. Mount cruci-

from 25 to 200 g.p.h. in increments of approxi

ble on a filtering flask and wet pads

mately 25 g.p.h. and the corresponding pressure

with a few drops of tri-solvent. Apply

drops shall be measured and recorded

slight vacuum and lightly tap down the

ability. - Two filtering

4.5.4.4.2 Filtering

edges of the filter pads using a stirring

ability determinations shall be made under the test

rod with a smooth round end (Caution-

conditions shown in table III. A fresh flow-rate-

Do not tap with tweezers or sharp edged

Instrument as pad is easily punctured).

tested class 2 (or two class 1) element(s) shall be

used for each determination.

Using slight vacuum wash pads by

filtering three portions of tri-solvent.

Table III - Filtering ability determination

Dry in oven for 1 hour at 220 F, place

in dust free cabinet, cool for 1 hour

and weigh to nearest 0.1 milligram.

When a double pan balance is used a

similarly prepared crucible may be

used as a tare.

(c) Procedure. - Procedure shall be as

follows:

(1) Decant the fuel sample through a pre

water is added, a volume equal to the

pared and weighed crucible using a

amount of water added shall be withdrawn from

vacuum of about 18-20 inches Mer-

the filter case each 30 minutes and discarded.

cury (Hg) below atmosphere. If

necessary tap edges of filter pad with

stirring rod after adding first few

Solids addition rate shall be maintained at plus or

minus 1 percent of specified rate. Fuel tempera-

milliliter (ml) of fuel. Police sides

and

F.

ture shall be maintained between

and bottom of sample flask during

The relet pressure to the filter case shall be main-

recantation of last 50-100 ml of

tained at 25 1 p.s.i. Fuel temperature differen-

fuel Measure and record the size

of sample filtered. Wash the sides

tial pressure across the element(s) and fuel flow

rate shall be recorded each 10 minutes. Solids

and bottom of the sample flask three

times with tri-solvent and filter the

content of the fuel at the start of the test shall not

washings Reduce the vacuum to

exceed 1.0 milligrams per liter One-liter eff-

luent samples shall be taken at 10 minute intervals

about 2 inches Hg below atmospheric

during the first hour and at 30 minute intervals for

and wash the pad three times, filling

the remainder of the test. The test shall be con-

the crucible with the solvent on each

tinued until 200 grams of solids have been added or

washing. Dry and weigh using a tare.

until an element failure has occurred prior to the

4.5.4.3.1 Alternate method of sample analyses -

addition of the required amount of solids.

Samples may be analyzed for solids content by filter-

4.5.5 Differential pressure test (element). -

ing through an AA Millipore filter, drying and weigh-

One class 2 or two class 1 element(s) shall be

ing when specifically approved by the bureau or agency

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |