|

|||

|

Page Title:

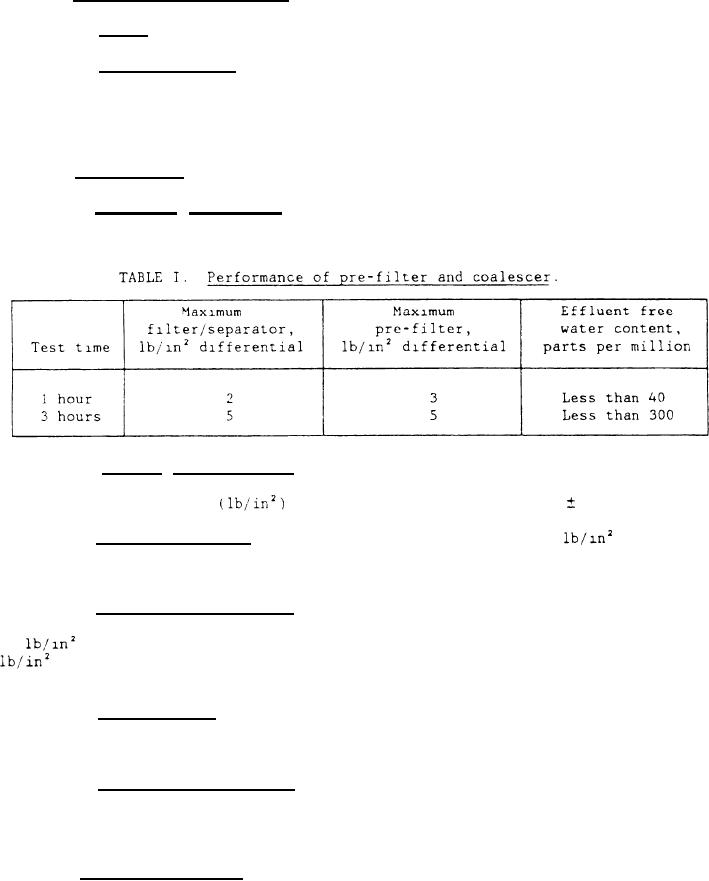

Table I. Performance of Pre-filter and coalescer |

|

||

| ||||||||||

|

|  MIL-F-24666(SH)

3.3 Design and construction.

Seals shall be synthetic rubber in accordance with MIL-R-7362.

3.3.1

Seals.

Filter elements shall be as shown on figure 1 and

3.3.2 Filter elements.

as specified herein. Gaskets shall prevent cocking of the element during instal-

lation. Filters shall be the full-flow type rated at 50 gallons per minute

(gal/min) with flow through the element from "outside-in". The design shall be

such that the filter element cannot be installed in reverse.

3.4 Performance.

3.4.1 Coalescer protection. When tested in series with referee coalescer

elements (4.7.3) in a filter/separator and subjected to the tests specified in

4.7.3.1, the pre-filter performance shall be as specified in table I.

3.4.2 Element pressure drop. The pressure drop through an as received

clean element using MIL-H-5606 at rated flow of 50 gal/rein shall not exceed

4 pounds per square inch

at 100 degrees Fahrenheit (F)

5F.

3.4.3 Element collapse. The elements shall withstand 180

differential pressure when tested by the procedure in 4.7.5 without evidence

of structural degradation.

Element dirt capacity shall be a minimum of

3.4.4 Element dirt capacity.

190 grams of Air Cleaner Fine Test Dust (ACFTD) to a differential pressure of

differential, and 210 grams of ACFTD to a differential pressure of 30

15

differential, across the filter element tested by the procedure described

No clean-up filter shall be used.

in 4.7.6.

3.4.5 Flow fatigue. The elements shall withstand the flow fatigue cycles

Element integrity shall be established by measurement of

specified in 4.7.7.

filtration efficiency ratios (see 4.7.7.2).

3.4.6 Fabrication integrity. The minimum bubble point values shall be

established by the filter manufacturer which will yield elements that will fully

meet all the requirements of this specification. Elements submitted to the

quality conformance bubble test shall meet the minimum values established herein.

The filter element shall operate throughout a

3.5 Temperature range.

temperature range of 40 to 160F.

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |