|

|||

|

Page Title:

Torque test of rotor stop stud (eccentric pin). |

|

||

| ||||||||||

|

|  MIL-F-48877A (AR)

4.5.11 Torque test of rotor stop stud (eccentric pin). The

required torque shall be applied between the rotor stop stud and

gear assembly. The required force shall act on the gear

assembly. Any rotor stop stud that does not comply with the

drawing requirement shall be classed defective.

4.5.12 Load test of detonator. Apply an axial load of 5

pounds perpendicular to the rotor and in such a direction as to

test the strength of the speed clip holding the detonator in the

rotor. Any speed clip that moves more than .005 inch shall be

classed defective and the S&A removed from the lot.

WARNING:

This test may be dangerous and should be performed

behind a suitable barricade.

4.5.13 Continuity through detonator test. The S&A shall be

armed in the case and the resistance measured between terminals

three and four. The value shall be 3.5 1.5 ohms. After the

test, the acceptable S&A's shall be disarmed and returned to the

line for further assembly Any S&A failing the requirement shall

be classed defective and removed from the lot.

Any continuity measurement which passes electrical

CAUTION:

current through the detonator shall be limited to one

milliampere maximum.

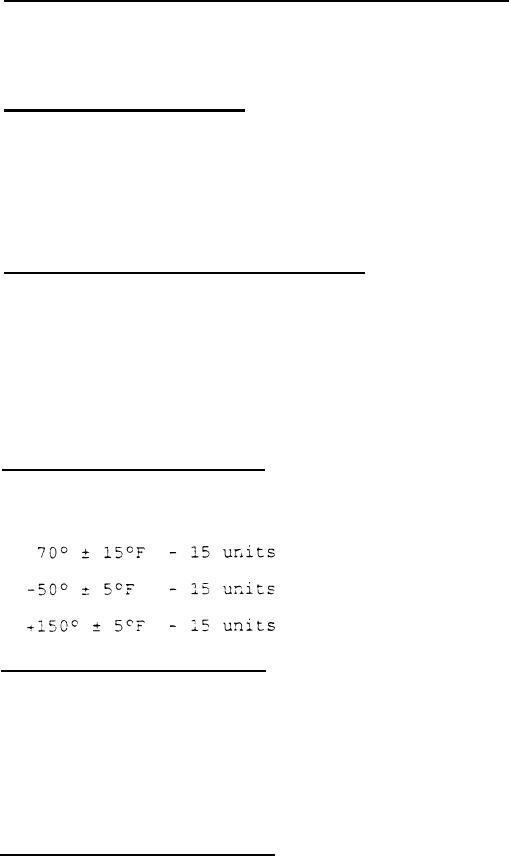

4.5.14 Temperature conditioning. Prior to the centrifuge

test (4.5.15 and 4.5.16), the sample shall be conditioned for a

minimum of two hours after temperature stabilization at the

following temperatures:

4.5.15 M439 S&A non-arming test. The S&A in the safe

position and in the horizontal plane with the G-weight located in

the downward direction (closest to earth), shall be assembled to

the test equipment in accordance with 4.4.3. The equipment shall

accelerate the loaded Safety and Arming Device in a clockwise

direction to 12.0 g's minimum for a minimum of five (5) seconds.

Observation shall be made for rotor in the safe position. S&A' S

failing to comply with the specified requirement shall be classed

defective and removed from the lot.

4.5.16 M439 S&A arming time test. The S&A in the safe

position and in the horizontal plane with the G-weight located in

the downward direction (closest to earth), shall be assembled to

the test equipment in accordance with 4.4.3. The equipment shall

68

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |