|

|||

|

|

|||

| ||||||||||

|

|  MIL-F-5577B

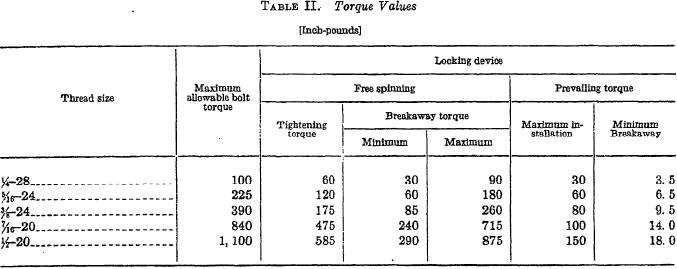

greater than 1,000 psi. The bolts shall be so

total indicator reading (TIR). Alternate pro-

selected that when the torque required to effect

cedures of equivalent sensitivity may be used if

the maximum pressure is applied, 75 percent

approved by the procuring activity.

of the maximum allowable torque specified in

3.6.3 Sealing pressure (class A). Fittings

table II shall not be exceeded. Multibolt fit-

shall be designed to effect a satisfactory seal

when a minimum pressure of 600 psi is applied

tings utilizing -28 bolts shall be designed to

be torqued between 25 and 35 inch-pounds, ex-

to the sealing surface. To prevent cold-flow,

cept when self-locking inserts are utilized.

the maximum sealing pressure shall be not

3.8 Class C fittings.

3.7 Class B fittings.

3.8.1 Assembly fittings (not cell mounted).

3.7.1 Wicking (class B). Fittings shall be

so designed and constructed that fluid wickage

See 6.3.1.

3.8.1.1 Sealing surface flatness.

will not occur into the tank construction.

3.8.1.1.1 Sealing surface flatness (free state).

3.7.2 Sealing surface flatness (class B).

Surface shall be so designed that the variation

Same requirement as 3.6.2.

in flatness of the sealing surface in a free state

3.7.3 Sealing pressure (class B). Fittings

shall not exceed 0.001 inch TIR. The surface

utilizing rubberized fabric sealing surfaces

shall be designed to effect a satisfactory seal

shall be normal to the centerline of the fitting

within 1 degree.

when a minimum pressure of 1,200 psi is ap-

3.8.1.1.2 Sealing surface flatness (gasket in-

plied to the sealing surface. To prevent cold-

stalled). When a transparent acrylic plate of

flow, the maximum sealing pressure shall be

1 inch minimum thickness is placed on the sur-

not greater than 1,500 psi. However, fittings

face with the appropriate gasket installed, and

utilizing a rubber surface to effect a seal shall

the bolts torqued to 60 percent of the nominal

be designed for minimum and maximum pres-

installation torque, 75 percent of the sealing-

sures of 600 and 1,000 psi, respectively. Bolts

surf ace width (minimum surf ace across which

shall be so selected that when the torque re-

fuel must travel to reach atmosphere) shall be

quired to effect the maximum pressure is ap-

in contact with the plate. The plate shall be

plied, 75 percent of the maximum allowable

flat to within 0.0005 inch TIR. Alternate pro-

torque specified in table I shall not be exceeded.

Multibolt fittings utilizing -28 bolts shall be

cedures of equivalent sensitivity may be used

if approved by the procuring activity.

designed to be torqued between 45 and 55 inch-

pounds when rubberized fabric is used to effect

3.8.1.2 "0" ring groove depth. When at-

a seal, and between 25 and 35 inch-pounds when

tached to a rigid plate that is flat and parallel

within 0.0005 inch TIR, the depth of the groove

a rubber surface is utilized, except when self-

locking inserts are utilized.

shall be within the tolerances specified in the

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |