|

|||

|

|

|||

| ||||||||||

|

|  MIL-F-5577B

All critical dimensional characteristics shall be

4.4.2 Methods of tests. Unless otherwise

inspected.

specified, the methods used in conducting tests

4.5.1.1 Surface blemishes. Surface blem-

described herein shall conform to the appli-

mishes such as flow cracks, porosity, blisters,

cable method of Fed. Test Method Std. No.

pockmarks, and tears shall be inspected tO in-

601.

spection standards approved b-y the procuring

4.4.3 Test jig. The test setup for the vibra-

activity.

tion phase shall be in accordance with figure 1;

4.5.1.2 Detailed inspection (for samples

however, the setup of figure 2 may be modified

only). The fittings shall be inspected to deter-

for this use if approved by the procuring activ-

mine conformance to the dimensions of the

ity.

applicable drawings.

4.5 Test methods.

4.5.2 Physical-property test (classes A and

4.5.1 Inspection. Each fitting submitted for

B).

acceptance under contract shall be carefully ex-

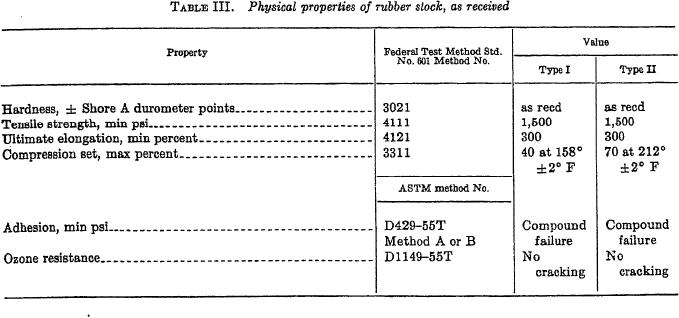

4.5.2.1 Physical properties. Rubber stocks

amined to determine conformance to all the

used for Class A fittings and the sealing sur-

requirements of this specification for which no

faces of Class B fittings shall have the physical

specific tests are described, and to determine

properties listed in table III when tested in

conformance to manufacturer's approved ma-

accordance with the methods indicated in table

III.

terial, fabrication specifications, and drawings.

to immersion in alcohol conforming to Specifi-

4.5.2.2 Fluid aging.

cation MIL-A-6091 for 48 hours. After ag-

4.5.2.2.1 Fuel aging. Specimens of rubber

ing, the specimen shall be tested for the physi-

stocks for type I fittings shall be subjected to

cal properties listed in table IV within 3 minu-

immersion in medium No.6 fluid for 72 hours.

tes after removal. Calculation of tensile

After aging, the specimen shall be tested for the

strength and adhesion shall be based on the

physical properties listed in table III, within 3

cross-section areas of the specimen before im-

minutes after removal. Calculation of tensile

mersion.

strength and adhesion shall be based on the

4.5.2.3 Oil aging. Specimens of type I and

cross-section areas of the specimen before

type II fitting rubber stocks shall be subjected

immersion.

to. immersion in mediuun No. 1 oil at tempera-

4.5.2.2.2 Alcohol aging. Specimens of rub-

tures of 215 F and 275 F, respectively, for 70

ber stock for type I fittings shall be subjected

hours. After this aging, the specimens shall

8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |