|

|||

|

|

|||

| ||||||||||

|

|  MIL-G-24477(SHIPS)

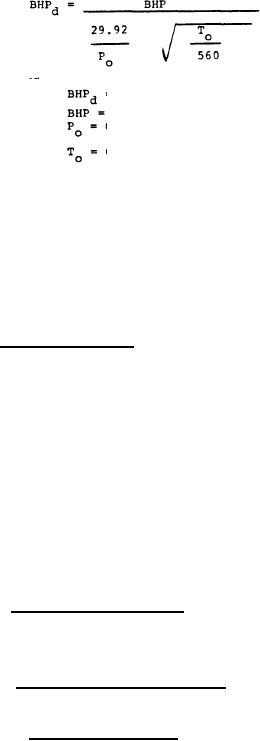

obtained under standard conditions. The dynamometer load necessary to satisfy this require-

ment shall be determined using the following formula:

Where:

Dynamometer load (observed).

Engine identification plate output.

Observed ambient pressure in inches of Hg

(dry barometer).

Observed ambient temperature (absolute).

The correction factor shall be applied for all dynamometer test loads.

4.4.1.1 The exhaust and intake system to the engine, shall be provided with valves

capable of varying the engine blower intake vacuum from O to 7 inches of Hg. and the exhaust

pressure up to 15 p.s.i. Means shall be provided to control both intake and exhaust valves

manually or by an automatic mechanism which will follow the simulated test cycles specified

herein.

4.4.1.2 The temperature cf the raw water to the engine shall be a minimum of 90F.

The engine fresh water shall be treated to prevent corrosion.

4.4.1.3 Fuel used during the tests shall be diesel fuel corresponding to MIL-F-16884.

4.4.2 First unit tests.

4.4.2.1 Surface endurance test. The exhaust back pressure at

the engine exhaust outlet

and blower inlet vacuum for rateed and speed shall be adjusted to

3 p.s.i. and 1 inch Hg.

respectively. The engine shall be run for 125 eight hour cycles as

follows (the system shall

meet performance requirements and no shutdown shall be permitted due

to system malfunction) :

2 hours at rated load and speed.

(a)

1 hour at 85 percent load and rated speed.

(b)

10 minutes at minimum idling load and speed.

(c)

1 hour and 50 minutes at rated load and speed.

(d)

10 minutes at minimum idling load and speed.

(e)

30 minutes operation at 50 percent load and rated speed.

(f)

10 minutes at minimum idling load and speed.

(g)

10 minutes at 85 percent load and rated speed.

(h)

1 hour and 50 minutes at 110 percent rated load at rated speed.

(i)

10 minutes shutdown (minimum between each cycle).

(j)

Engines may be shut-down, as required, between each complete cycle or full cycles may be run

on a continuous basis.

4.4.2.2 Fuel consumption test. Fuel consumption tests of 1/4 hour duration with inter-

vals between each run for stabilization of operating conditions, shall be made for each load

of O, 40, 80, 100 and 110 percent of rates hp. Fuel consumption shall be corrected for the

difference in high heat value of the fuel actually used during the test and the standard

19,350 British thermal unit (B.t.u.) per pound.

4.4.2.3 Spectrometric oil analysis. Lubricating oil samples shall be taken from the

lube oil scavenge line before oil filter with the engine running. The oil must be

circulating and at operating temperature. Samples shall not be taken from a gage line.

4.4.2.3.1 Sampling intervals. Samples shall be drawn during the 2 hours at rated load

and speed period of the first and last cycle specified in 4.4.2.1 and during the same period

of each ten cycles during the test (total 14 samples).

4.4.2.3.2 A spectrometric analysis of each oil sample taken in accordance with 4.4.2.3.1

shall be made. The concentration of elements in ppm of oil wetted wearing parts shall be

recorded. The analysis shall identify and measure the following elements, as applicable, in

21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |