|

|||

|

Page Title:

Table III. Strength requirements. |

|

||

| ||||||||||

|

|  MIL-DTL-13220D

3.3.2 Zinc. Zinc plated in accordance with ASTM-B633, code letter Z.

3.3.3 Passivation. Passivate corrosion resistant steel in accordance with SAE AMS 2700,

code letter E.

3.4 Salt spray. When fittings are exposed to salt spray testing specified in 4.8 , the plating shall show

no corrosion products of zinc or basis metal corrosion products. The appearance of corrosion products

visible to the unaided eye at normal reading distance shall be cause for rejection, except white corrosion

products at the edges of the specimens shall not constitute a failure.

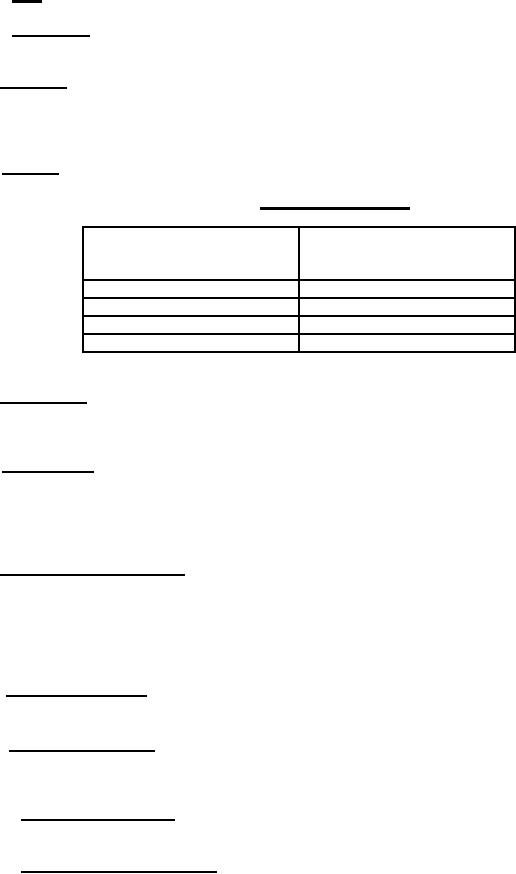

3.5 Strength. Strength requirements of the hooks shall be as shown in table III.

TABLE III. Strength requirements.

Hook

Safe working load - Pounds

wire rope diameter -

(metric)

Inches(metric/decimal)

(1.27cm/.05in )

3,300 (1497kg)

6/8 ( 1.91cm/.75in)

5,000 (2268kg)

(1.91cm/.75in )

8, 000 (3629kg)

7/8 and 1 (2.22cm/.87in )

15, 000 (6804kg)

3.6 Identification. The choker hooks shall bear the manufacturer's identification mark and hook size.

The identification shall be stamped, or applied by any other method of permanent marking, on the hooks

in a clearly visible location.

3.7 Workmanship. Workmanship shall conform to accepted commercial standard practice for this

type of equipment. Castings should be clean and high quality. There shall be no fins, spurs, scale,

extraneous material, cracks, porosity, sand, inclusions, blowholes, rough edges, or rough surfaces.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as

follows:

a. First article inspection (see 4.3).

b. Conformance inspection (see 4.4).

4.2 Inspection conditions. Unless otherwise specified, all inspections shall be performed in

accordance with the applicable test procedures.

4.3 First article inspection. First article inspection, if not done by the manufacturer, shall be

performed at a laboratory acceptable to the procuring activity on sample units produced with equipment

and procedures used in production.

4.3.1 Samples for first article. Samples for first article shall be representative of the products

proposed to be furnished to this specification. Sampling shall be in accordance with 4.5.1.

4.3.2 First article inspection routine. All samples shall be subjected to first article testing in

accordance with table IV.

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |