|

|||

|

|

|||

| ||||||||||

|

|  MIL-H-62185(AT)

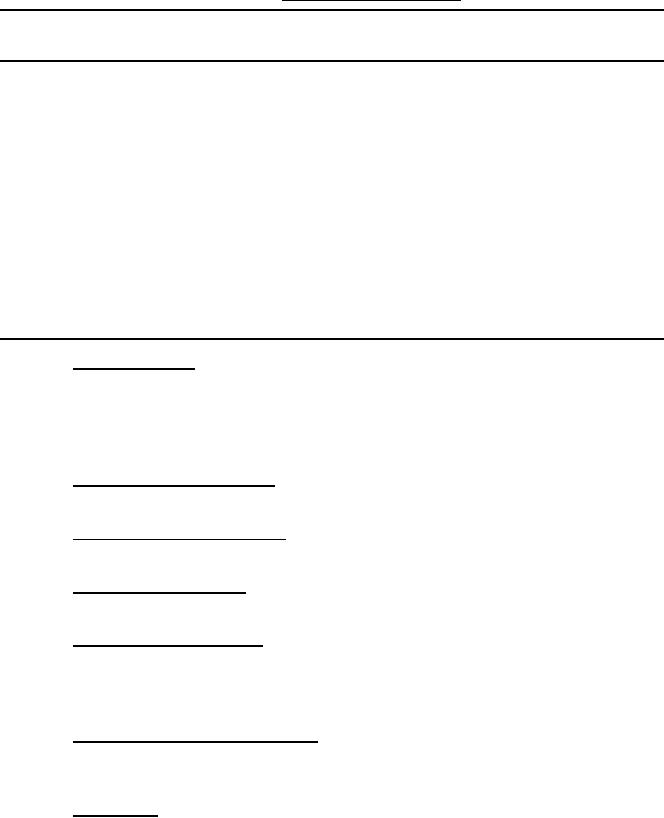

Table VI. - Location for Tests (Cont'd)

Title

Paragraph

Place of

Government

Number

Manufacture

Proving Ground

Comparison tests

4.5.3

X

Winterization equipment test

4.5.3.2

X

Carbon monoxide concentration test

4.5.3.3

X

Cooling system tests

4.5.3.4

X

Communications equipment test

4.5.3.5

X

Temperature operational tests

4.5.3.6

X

Air cleaner operational check

4.5.3.7

X

Water removal (bilge pump) test

4.5.3.8

X

Speeds with towed load test

4.5.3.9

X

Climbing test

4.5.3.10

X

Slope operational test

4.5.3.11

X

Trench crossing test

4.5.3.12

X

Vertical obstacle test

4.5.3.13

X

Radio suppression test

4.5.3.14

X

4.5.1.2 Hatch seal check. To determine conformance to 3.4.1.3, the batch shall be closed

and locked, a spray of free flowing water directed on hatch for a period of 3 minutes without

evidencing leakage. After 2 minutes, following the 3 minute spray period, the hatch shall be

opened and no water shall enter the vehicle. This test may be conducted during shallow water

fording.

4.5.1.3 Controls and linkage checks. To determine conformance to 3.4.4, 3.4.5 all controls,

and throttle linkage shall be operated and checked for functional requirements.

4.5.1.4 Adjustment mechanism check. To determine conformance to 3.4.6, all adjustment

mechanisms shall be checked for proper adjustment and functional requirements.

4.5.1.5 Fastener and lock check. To determine conformance to 3.4.7, all fastener and

locking devices shall be operated and checked for positive fastening and locking.

4.5.1.6 Fuel system leakage check. To determine conformance to 3.4.8 through 3.4.8.2, the

fuel system shall be pressurized with dry air at a pressure of 3 to 4 pounds per square inch (psi),

prior to engine installation, and check fittings, lines, and fuel tank seals for leaks; by applying

soapy water or equivalent.

4.5.1.7 Hydraulic reservoir and line check. To determine conformance to 3.4.9, prior to

initial operation of the hydraulic system the reservoir and lines shall be checked for leaks and

cleanliness.

4.5.1.8 Light check. To determine conformance to 3.4.11.1, all lights shall be operated

during and after break-in run throughout all stages of operation, and checked for functional

requirements.

22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |