|

|||

|

|

|||

| ||||||||||

|

|  MIL-L-40064E

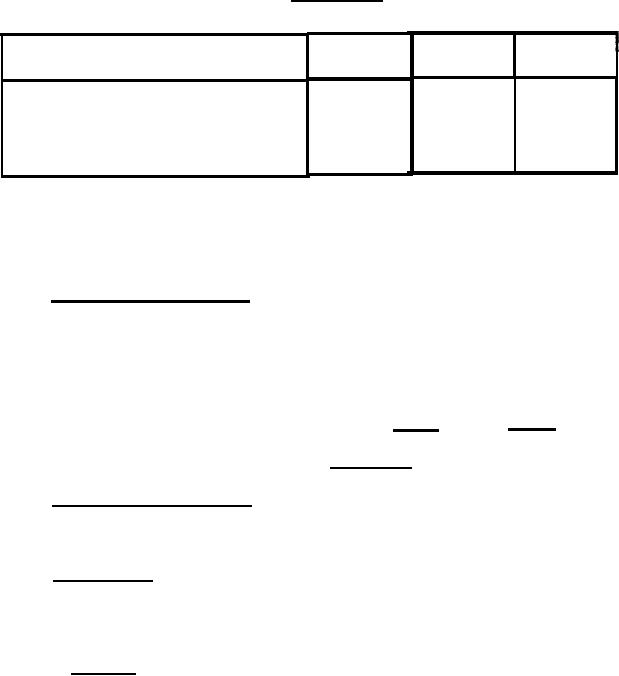

Dimensions.

TABLE I.

Type III

Type II

Type I

(inches)

(inches)

(inches)

64

96

64

Width at platform end (overall)

Width at railcar or truck end

64

70

64

(overall)

44

48

44

Length (overall)

Note:

A tolerance of plus or minus 1 inch shall be allowed on the

above dimensions.

3.7 Identification marking. Each loading plate shall be marked in accor-

dance with MIL-STD-130. Each loading plate shall have an identification plate

conforming to MIL-P-15024, type A. The plate will be securely attached in an

protected location. The following information shall be permanently marked,

as applicable, on the name plate in characters not less than 0.375 inches:

Loading Plate

MIL-L-40064, Type

Style

Company Name

pounds

Capacity:

3.8 Treatment and painting. The style B loading plates shall be cleaned,

treated, and painted in accordance with MIL-T-704, type A, color No. 13538

of FED-STD-595. Style A loading plates shall be cleaned only.

3.9 Workmanship. All loading plates shall be clean and properly

assembled. Burrs shall be removed and sharp edges shall be rounded.

Parts shall not be damaged or impaired in any way, and parts shall show

no evidence of rust or corrosion.

3.9.1 Welding. All surfaces of parts to be welded shall be free from

rust, scale, paint, grease, and other foreign matter. parent materials. weld

filler metals, and fabrication techniques shall be as required to enable the

loading plate to conform to the examination and test requirements specified

in section 4. Parts to be joined by welds shall be brought into as close

contact as possible and in no event shall be separated by more than 0.18

inch unless appropriate bridging techniques are used. The welding process

used in fabrication shall be at the option of the contractor. Aluminum

alloy welding and inspection shall be in accordance with MIL-W-22248, class 3.

Welding shall be inert gas shielding. Welds shall be inspected for good

adhesion, no porosity and good penetration.

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |