|

|||

|

Page Title:

Inspection of packaged containers |

|

||

| ||||||||||

|

|  MILL87177A

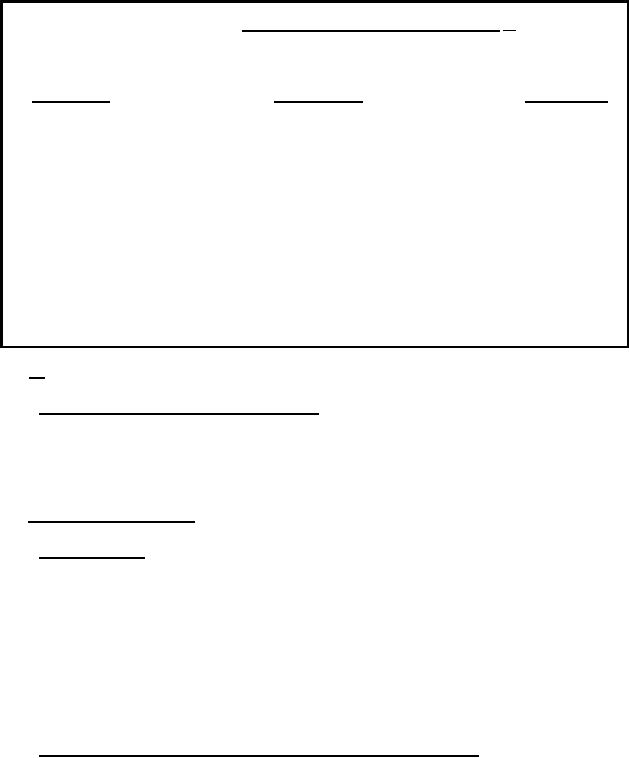

TABLE III. Quality conformance inspection 1 /

Requirement

Test

Inspection

paragraph

paragraph

Grade A

3.4.3

4.4, 4.5

Corrosivity

4.6, 4.6.7

Grade B

3.4.4

4.4, 4.5

Corrosion resistance

4.6, 4.6.8

Leakage

3.4.1.1

4.6.4

Contents

3.4.1.2

4.6.5

Performance of

3.4.1.3

4.6.6

pressurized containers

1/ Refer to 4.5.

4.5.4 Inspection of packaged containers. The packaging containers, packing, and mark-

ing of type I and type II compound shall be inspected to determine conformance to the

requirements of section 5. Selection shall be in accordance with MILSTD105, inspec-

tion level S2, 2.5 percent defects per 100 units. Sample units used in sampling plans

A and B shall be used for this inspection (see 4.4.2).

4.6 Method of inspection

4.6.1 Dryness test. Three test disks (4.3.2.2) prepared as specified in 4.3.2.3 shall be

cleaned as specified in 4.3.2.4, coated as in 4.3.2.5, and allowed to hang in a vertical

position for two hours. They shall then be weighed and completely immersed vertically

in talcum powder and withdrawn immediately. They shall then be reweighed to the

nearest 0.0001 gram. The average change in weight shall be recorded. This procedure

shall be repeated with test disks which have not been coated. These shall be used as

controls. The average weight increase of the coated panels as compared with the

weight increase of the uncoated panels shall be the measure of dryness.

4.6.2 Grade A synthetic sea water displacement procedure. Panels prepared as

specified in 4.3.2.3 and 4.3.2.4 shall be so placed that one 2inch end shall be raised

one inch above a horizontal surface. The panels shall then be sprayed with the

synthetic sea water so that the entire upper surface of specimen is covered with tiny

droplets. Within one minute after spraying, one milliliter of the test compound shall be

poured along the upper 2inch edge of the panels and allowed to run slowly down the

specimen so as to completely cover the test panel. After another minute, a second

milliliter of the test compound shall be poured and allowed to run down the panels in a

like manner. After waiting an additional minute, the panels shall be picked up and held

in a vertical position for one minute and shall then be placed flat (test side up) above

distilled water at 7F in a closed desiccator. After 24 hours they shall be removed and

cleaned with mineral spirits, and then evaluated for presence of visible corrosion.

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |