|

|||

|

|

|||

| ||||||||||

|

|  MIL-M-38510/101H

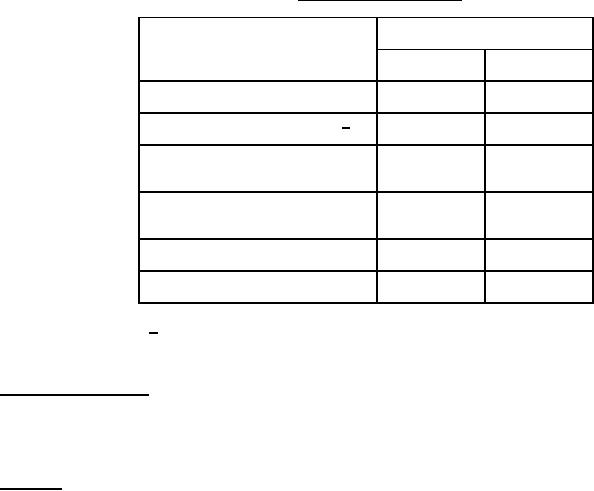

TABLE II. Electrical test requirements.

MIL-STD-883

Subgroups (see table III)

test requirements

Class S

Class B

devices

devices

Interim electrical parameters

1

1

(method 5004)

Final electrical test parameters 1/

1,2,3,4

1,2,3,4

(method 5004)

Group A test requirements

1,2,3,4,5,6,

1,2,3,4,5,6,7

(method 5005)

7,8A,8B,12,

13A,13B

Group C end point and group B,

1,2,3, and

1 and table IV

class S, electrical parameters

table IV delta

delta limits

(method 5005)

limits

Additional electrical subgroups

Not applicable

8A,8B,12,

For group C periodic inspections

13A,13B

Group D end point electrical

1,2,3

1

parameters (method 5005)

1/ PDA applies to subgroup 1 (see 4.2d).

4. QUALITY ASSURANCE PROVISIONS

4.1 Sampling and inspection. Sampling and inspection procedures shall be in accordance with MIL-M-38510 and methods

5004, 5005, and 5007, as applicable, of MIL-STD-883, except as modified herein. For devices marked with the "Q"

certification mark, sampling and inspection procedures shall be in accordance with MIL-PRF-38535 or as modified in the

device manufacturer's Quality Management (QM) plan. The modification in the QM plan shall not effect the form, fit, or

function as function as described herein.

4.2 Screening. Screening shall be in accordance with method 5004 of MIL-STD-883, and shall be conducted on all devices

prior to qualification and quality conformance inspection. The following additional criteria shall apply:

a.

Burn-in (method 1015 of MIL-STD-883).

1.

For class S devices: Test condition D using the circuit shown on figure 7.

2.

For class B devices: Test condition D using the circuit shown on figure 7 or test condition C using the circuit

shown on figure 8, or test condition F using the circuit (or equivalent) shown on figure 9.

b.

Reverse bias burn-in (method 1015 of MIL-STD-883). For class S devices only using the circuit shown on figure 8.

c.

Interim and final electrical test parameters shall be as specified in table II, except interim electrical parameters test

prior to burn-in is optional at the discretion of the manufacturer.

d.

The percent defective allowable (PDA) for class S and class B devices shall be as specified in MIL-M-38510, based

on failures from group A, subgroup 1 test after cooldown as final electrical test in accordance with method 5004 of

MIL-STD-883 and with no intervening electrical measurements. If interim electrical parameter tests are performed

prior to burn-in, failures resulting from pre burn-in screening may be excluded from the PDA. If interim electrical

parameter tests prior to burn-in are omitted, then all screening failures shall be included in the PDA. The verified

failures of group A, subgroup 1 after burn-in divided by the total number of devices submitted for burn-in in that lot

shall be used to determine the percent defective for that lot, and the lot shall be accepted or rejected based on the

PDA for the applicable device class.

14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |