|

|||

|

|

|||

| ||||||||||

|

|  MIL-M-38510/108A

4.5.2 Life test cooldown procedure. When devices are measured at 25C following application of the operating life or burn-in

test condition, they shall be cooled to within 10C of their power stable condition room temperature prior to removal of the bias.

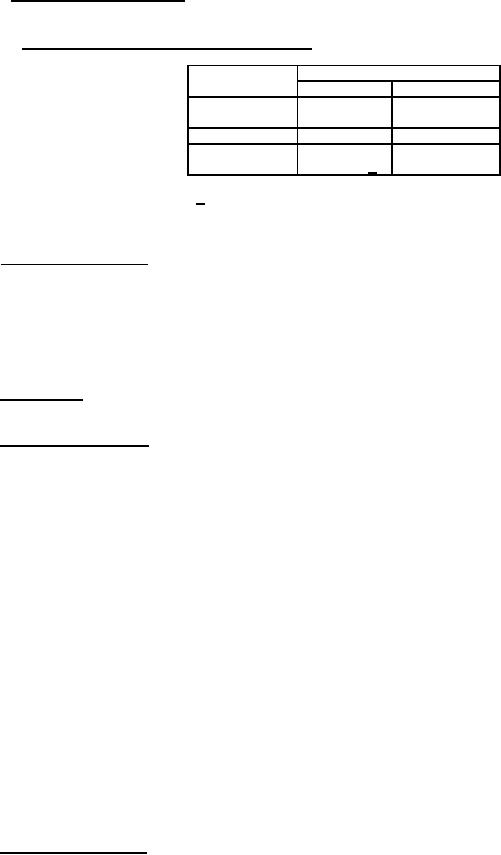

Table IV. Groups B and C end point electrical parameters (TA = 25C).

Device types 01 and 02

Test

Limit

Delta

0.010 V

VBE

0.600 V min

0.800 V max

|VBEQA VBEQB|

2.0 mV

10%

hFE

70 min

300 max 1/

1/ The 300 max limit applies to device type 01 only.

5. PACKAGING

5.1 Packaging requirements. For acquisition purposes, the packaging requirements shall be as specified in the contract or

order (see 6.2). When actual packaging of materiel is to be performed by DoD or in-house contractor personnel, these

personnel need to contact the responsible packaging activity to ascertain packaging requirements. Packaging requirements are

maintained by the Inventory Control Point's packaging activity within the Military Service or Defense Agency, or within the

military service's system command. Packaging data retrieval is available from the managing Military Department's or Defense

Agency's automated packaging files, CD-ROM products, or by contacting the responsible packaging activity.

6. NOTES

6.1 Intended use. Microcircuits conforming to this specification are intended for original equipment design applications and

logistic support of existing equipment.

6.2 Acquisition requirements. Acquisition documents should specify the following:

a.

Title, number, and date of the specification.

b.

Complete part number (see 1.2).

c.

Requirements for delivery of one copy of the quality conformance inspection data pertinent to the device

inspection lot to be supplied with each shipment by the device manufacturer, if applicable.

d.

Requirements for certificate of compliance, if applicable.

e.

Requirements for notification of change of product or process to acquiring activity in addition to

notification of the qualifying activity, if applicable.

f.

Requirements for failure analysis (including required test condition of MIL-STD-883, method 5003),

corrective action and reporting of results, if applicable.

g.

Requirements for product assurance options.

h.

Requirements for special carriers, lead lengths, or lead forming, if applicable. These requirements should not

affect the part number. Unless otherwise specified, these requirements will not apply to direct purchase by

or direct shipment to the Government.

i.

Requirements for "JAN" marking.

j.

Packaging requirements (see 5.1).

6.3 Superseding information. The requirements of MIL-M-38510 have been superseded to take advantage of the

available Qualified Manufacturer Listing (QML) system provided by MIL-PRF-38535. Previous references to MIL-M-38510 in

this document have been replaced by appropriate references to MIL-PRF-38535. All technical requirements now consist of this

specification and MIL-PRF-38535. The MIL-M-38510 specification sheet number and PIN have been retained to avoid

adversely impacting existing government logistics systems and contractor's parts lists.

33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |