|

|||

|

Page Title:

Table 2. Functioning firing test schedule. |

|

||

| ||||||||||

|

|  MIL-M-45013E (AR)

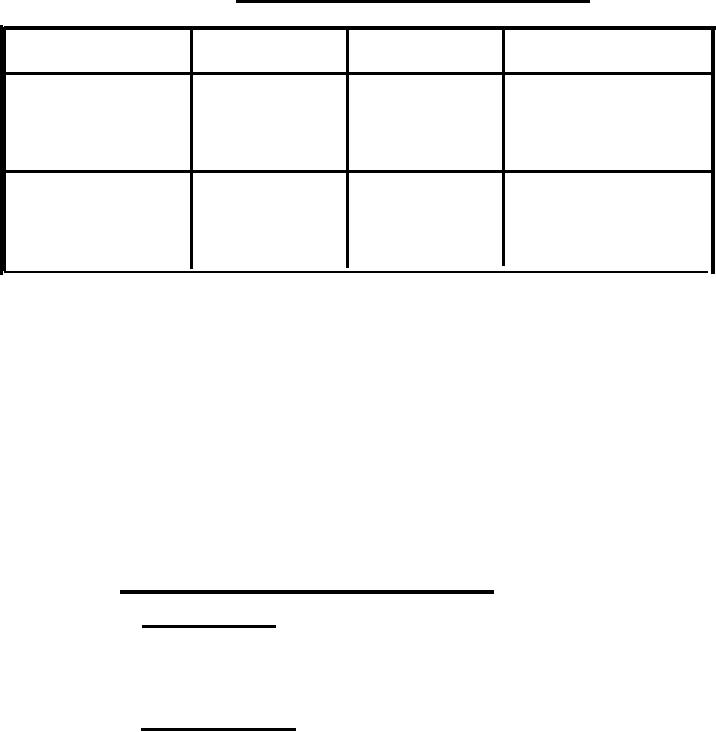

TABLES II. Functioning firing test schedule.

All Other

First 500

Type of Firing

Machine Guns

machine Guns

20 rounds

Interrupted

50 rounds

Assigned Barrel

Bursts 1/

One Continuous

20 rounds

50 rounds

Burst 2/

Interrupted

20 rounds

50 rounds

Spare Barrel

Burst 1l

One Continuous

20 rounds

50 rounds

Burst 21

1/

The trigger shall be intertionally released to stip firing at

least five times during the 50-round and at least two times

firing the 20-round interrupted burst firing.

2/ Rate of fire shall be measured and recorded on every tenth

machine gun during the continuous burst firing of each barrel

using a timer gage conforming to drawing 7273920. Failure of

any sample machine gun to meet the cyclic rate of fire

requirement shall be cause for measurement of the cyclic rate

of fire on the other nine machine guns represented. If any

one of the other nine machine guns fail the cyclic rate

requirement, the ten machine guns are rejected, and the

contractor shall perform a failure analysis and contact the

Procuring Agency for instructions. If none of the other nine

machine guns fail the cyclic rate requirement, only the

sample machine gun that failed shall be rejected.

4.5.6 Targeting and accuracy firing test.

4.5.6.1 Sight setting. Each machine gun shall be tested

with both its assigned and spare barrel assembly with biped

assembly with the same sight setting for compliance with the

targeting and accuracy requirements of 3.4.6. The ammunition and

links shall be in accordance with 4.4.4.3.

4.5.6.2 Firing fixture. Machine guns shall be tested using

the test fixture conforming to drawing 7273907. With the rear

sight set at zero indage and the elevation scale set so that the

scale retaining screw is approximately at the midpoint in the

slot, the sight aperture slide shall be brought to the elevation

setting indicated on the targeting and accuracy diagram. With

30

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |