|

|||

|

|

|||

| ||||||||||

|

|  MIL-M-48245B(AR)

Gamma-Glycidoxypropyltrimethoxy Silane (Dwg. 9277699)

Silica, Granular (Dwg. 9298447)

Silica, Powdered (Dwg. 9298444)

Foam Reducer

(Dow Corning Antifoam A or equivalent)

The viscosity of the base resin when

3.2 Base resin viscosity.

measured at 70F to 75F in accordance with 4.5.1, a minimum of

72 hours after the material is first compounded, shall not exceed

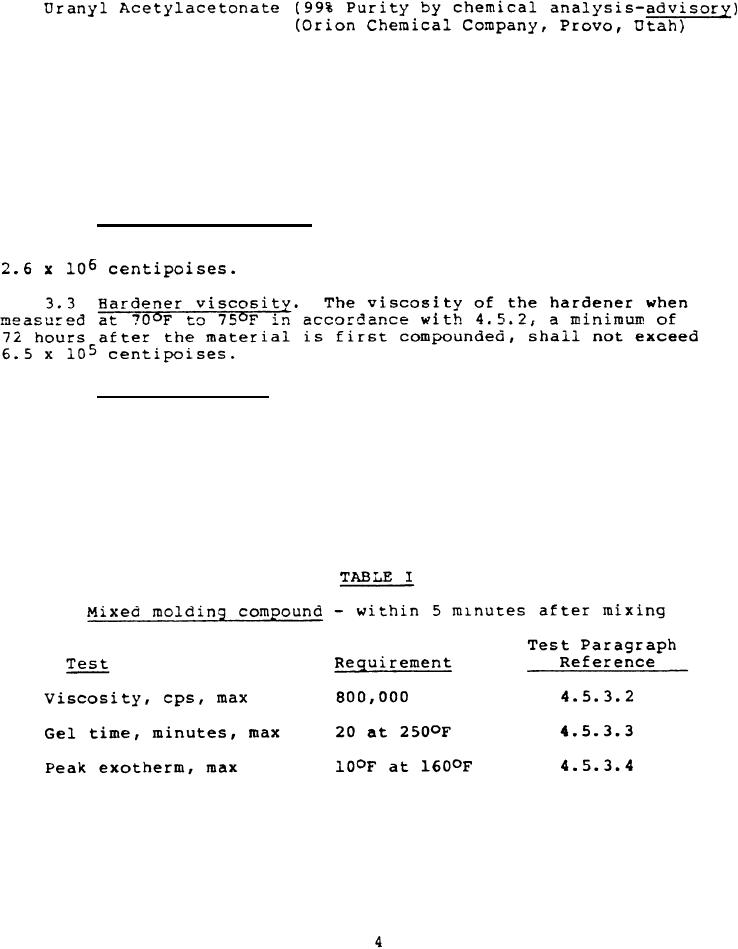

The molding compound, when prepared as

3.4 Molding compound.

specified in 4.5.3.1 and 4.5.4.1, shall comply with the requirements

specified in Table I and Table II when tested as specified in the

referenced test paragraphs.

The requirements apply to molding compound made from base resin

(Part A) and hardener (Part B) that have each been "wet out" (aged)

for seventy-two (72) hours minimum from the time they are first

compounded and prior to mixing together in the specified ratios to

make the molding compound.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |