|

|||

|

|

|||

| ||||||||||

|

|  MIL-P-17639F(SH)

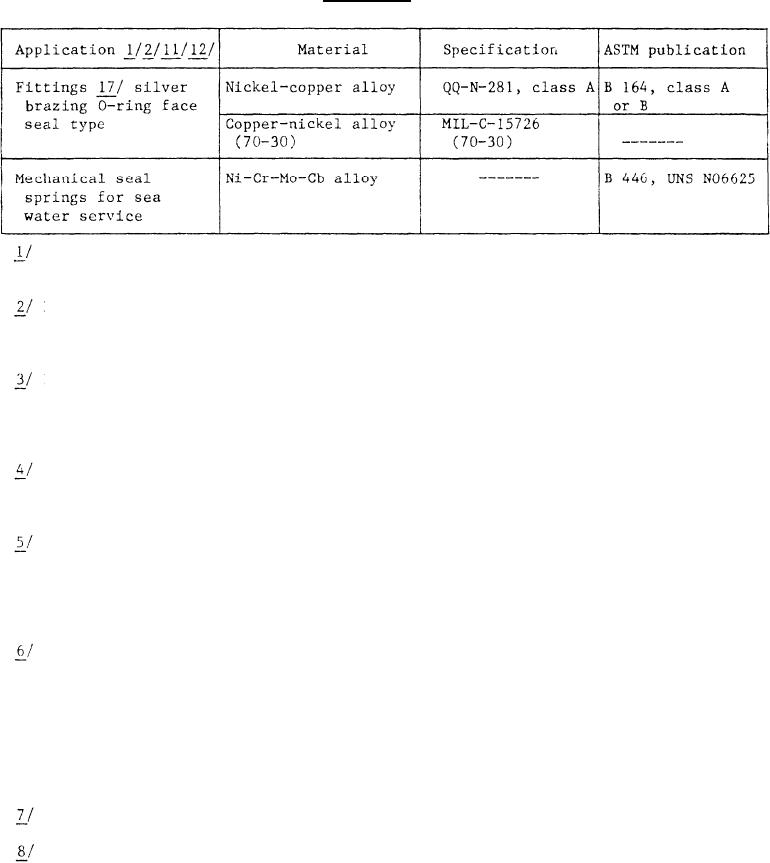

TABLE I.

Materials. - Continued

Subassembly parts which are used in a major pump part listed in table I and

which perform the same or similar functions as the major part (for example,

casing drain plug) shall be of a material specified for the major part,

Detail drawings and lists of q aterial shall reference the specification followed

in each case (preferably in the order specified in 3.6.2.1) and shall include

the class, type, or grade of material used in each case, as applicable. ASTM

materials shall not be used for submarine submergence boundary parts.

Post weld heat treatment is required for repairs to areas in which excavation

depth of 20 percent of wall thickness, or 1 inch, whichever is smaller is

realized, or when total cavity area exceeds 2 square inches. Post weld heat

treatment is not required for other repairs except by agreement between the

manufacturer and the purchaser.

The design of bolts, studs, and nuts shall be in accordance with MIL-S-1222,

in addition to the material specification specified in table I. Nickel-

copper-aluminum alloy bar stock used for threaded fasteners shall be as

specified in MIL-S-1222.

Nickel-copper alloy shall not be used for both male and female threaded

members in the same assembly. If bolts and studs in accordance with QQ-N-281,

class A, are used, they shall be hot finished for submarine sea water appli-

cation. Any nickel-copper bolts and studs made of cold drawn, stress-

relieved material for use in submarine pump parts shall be in accordance

with MIL-N-24106, class C in lieu of QQ-N-281.

A certificate of compliance with ASTM A 744 shall be provided. In addition,

certification of the chemical test results for each heat of material and

the specific heat treatment (including temperature and holding time) to

which each casting was subjected shall be provided. The time between

removing the stainless steel part from the furnace and quenching shall be

minimized. This certification shall list both chemical test result values

and the corresponding acceptance criteria value specified in ASTM A 744.

Repair welding shall be accompanied by post-weld heat treatment in accordance

with ASTM A 744 (see 6.2.2).

All nickel-copper-aluminum alloy parts shall be annealed prior to age-

hardening except parts for which a hardness greater than 265 Bhn is required.

For submarine sea water pumps, sleeves which are a seat for O-rings where

movement occurs, e.g., under mechanical seals which are spring loaded,

shall be nickel-copper alloy that is weld clad with Ni-Cr-Mo-Cb alloy.

The area to be weld clad shall be minimized. Cladding shall extend a

minimum of 3/16 inch deep in the final machined condition. Deposit shall

26

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |