|

|||

|

Page Title:

Table I. Permission thrust loads. |

|

||

| ||||||||||

|

|  MIL-P-17840C(SH)

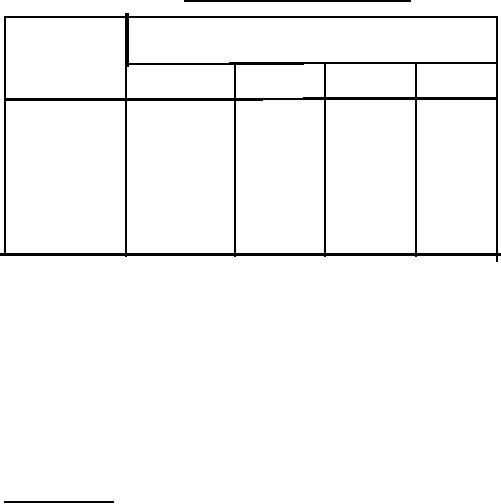

TABLE I. Permission thrust loads.

Bearing

Revolutions per minute (r/rein)

size

2800

3500

1150

1750

----

----

215

160

305

----

----

215

280

306

----

----

235

255

307

----

----

300

400

308

470

375

350

560

309

400

360

500

310

600

425

470

700

580

312

495

670

530

313

800

3.2.7.3 Anti-friction bearings shall be type 111, class 2, or type 120 in

accordance with FF-B-171. The sizes used for the various frames shall be as

shown on figures 3 and 5.

3.2.7.4 For installations utilizing the pump end bearing as the thrust

bearing, a bearing preload spring shall be provided and shall be installed

against the outer edge of the outer ring of the front end bearing. For

installations using the front end bearing as the thrust bearing, a bearing

preload spring shall be installed against the inner edge of the outer ring of

the pump end bearing.

3.2.8 Lubrication.

3.2.8.1 The lubrication of rolling contact bearings shall be in accordance

with FF-B-171.

3.2.8.2 The rolling contact bearing lubrication method shall prevent

bearing failure resulting from over-greasing. Bearing relubrication procedures

shall be accomplished with the unit secured.

3.2.8.3 Grease lubricants shall be in accordance with DOD-G-24508. The

design shall be such that any qualified grease under DOD-G-24508 can be used

interchangeably with any other qualified product to the same specification.

Bearings shall be capable of being relubricated without removing the bearings

and shall not require frequent lubrication if the pump is not operated over an

extended period of time.

3.2.8.4 Thrust bearing housings shall be so designed that the thrust

bearing will be adequately lubricated immediately when the shaft starts to turn.

This shall be accomplished by properly locating lubricant supply and drain

fittings and by adequate sealing of the bearing housings so that, regardless of

length of time the units are idle, an adequate supply of lubricant will remain

in the bearing housings.

8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |