|

|||

|

Page Title:

Table VI. Sampling. plan, acceptance and rejection |

|

||

| ||||||||||

|

|  MIL-P-20632B(SH)

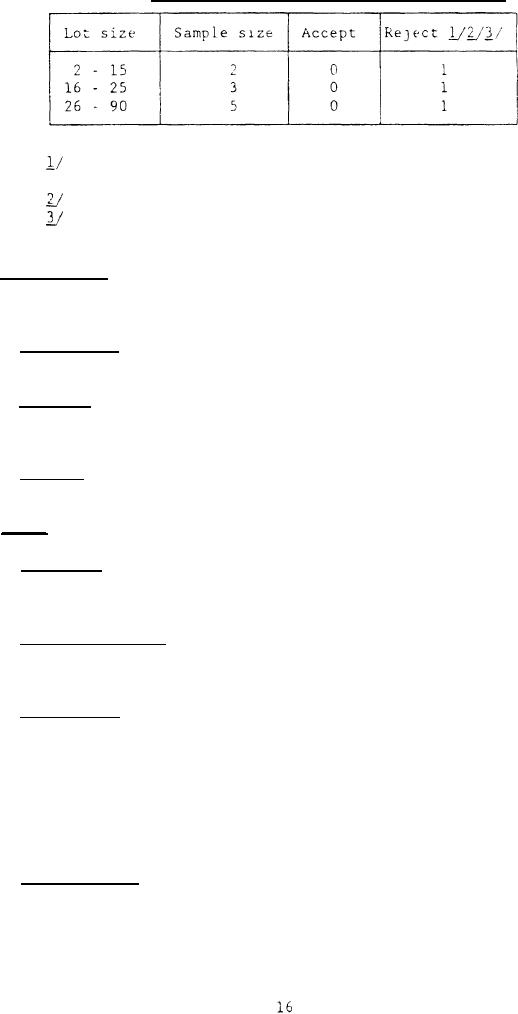

Sampling. plan, acceptance and rejection

TABLE VI

All defective items must be replaced with acceptable

items prior to lot acceptance.

Inspect sample size until rejection criteria is reached,

Rejected lots may be screened and resubmitted for

inspection and retest.

4.5 Examinations.

Every purifier shall be examined to ascertain that the

equipment is in accordance with all the requirements of this specification not

involving tests and as specified in 4.5.1 through 4.5.3.

Welding shall be examined to ensure conformance with

Fabrication.

4.5.1

3.3 18

4.5.2 Painting.

Every purifier shall be examined after the application of

each coat of paint to ensure conformance with the requirements specified in

3319

4.5.3 Workmanship.

Every purifier shall be examined to ensure conformance

with requirements for workmanship specified in 3 10

4.6

Purifiers shall be tested as specified in 4 6. 1 through 4 6 14

Tests.

4.6.1 Spin-test

Prior to Installation in the purifier, the bowl assembly

shall be spin-tescecl at . 125 percent of the maximum designed operating, speed for d

.

period of not less than 15 minutes

Every completely assembled purifier shall be

4.6.2 Operational test.

operated for a period of not less than 10 minutes at rated speed to validate

smoothness of running,, satisfactory operation of controls , and proper assembly

4.6.3 Driver test.

The purifier shall be operated at full capacity, as

Quantitative

specified in table I, for a period of not less than 1 hour

If the purifier is

measurements of purification are not required for this test

supplied with a motor controller (see 3.3.23), the motor controller supplied with

During this test, the brake

the purifier shall be used during this test

The type of fluid

horsepower input to the assembled purif ier shall be determined

circulated through the purifier during the test shall be the fluid specified for

the particular size and capacity (see 3.4.1)

The sample unit shall be tested for capacity to ensure

4.6.4 Capacity test.

The purifier shall be operated using turbine lube oil ,

conformance with 3. 4 1.

diesel lube oil and naval distillate fuel F-76, each for 1 hour, as specified in

For each fluid an effluent quality

table I, to determine the purifier capacity

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |