|

|||

|

|

|||

| ||||||||||

|

|  MIL-P-46183

3.3 Form. The form of the PEEK thermoplastic shall be granules, pellets or

powder. When specified by the procuring activity, the form shall be in the size

and shape specified (see 6.2).

3.4

Flammability and burning.

3.4.1 Oxygen index. The oxygen index for all types of PEEK thermoplastic shall

be 35% minimum (see 4.3). The thickness of the test specimen shall be 3.2 mm.

3.4.2 Specific optical density. The maximum specific optical density, Dmax, in

the flaming mode for all types of PEEK thermoplastic shall be 25 (see 4.3 and

6.3). The Dmax in the nonflaming mode shall be 5. Samples for smoke emission

tests in accordance with ASTM F 8l4 (see table V) shall be slabs

0.125 in thick x 3 in x 3 in (3.l mm thick x 76.2 mm x 76.2 mm).

3.5 Electrical properties. The electrical properties of the PEEK thermo-

plastic shall be as specified in table IV (see 4.3).

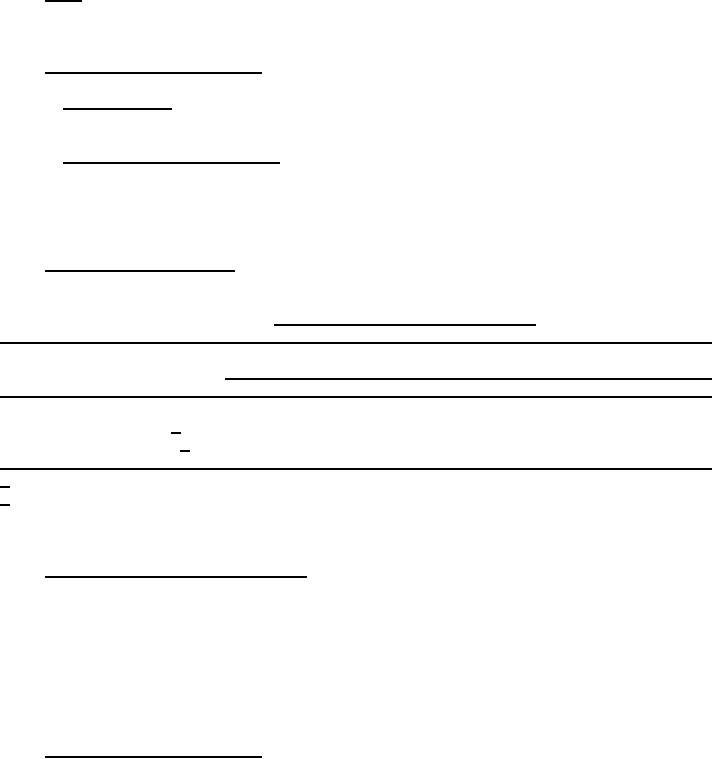

TABLE IV.

Electrical properties of PEEK.

Property

Minimum Property Values

Type I

Type II

Type III

(nonreinforced) (30% glass fiber) (30% carbon fiber)

1015 ohm-cm

1015 ohm-cm

Volume resistivity 1/

1200 ohm-cm

Dielectric strength 2/

400 volts/mil

450 volts/mil

----

(15.8 MV/m)

(17.7 MV/m)

1/

Volume resistivity in ohm-m has a value of 1/100 of the value in ohm-cm.

2/

The thickness of the test specimen shall be 0.125 in (3.1 mm).

4.

QUALITY ASSURANCE PROVISIONS

4.1 Responsibility for inspection. Unless otherwise specified in the contract

or purchase order, the contractor is responsible for the performance of all

inspection requirements as specified herein. Except as otherwise specified in

the contract or purchase order, the contractor may use his own or any other

facilities suitable for the performance of the inspection requirements specified

herein, unless disapproved by the Government. The Government reserves the right

to perform any of the inspections set forth in this specification where such

inspections are deemed necessary to ensure supplies and services conform to

prescribed requirements.

4.2 Classification of tests. The examination and testing of the plastic

molding and extrusion material shall be classified as follows:

a.

Preproduction tests

b.

Quality conformance tests

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |