|

|||

|

|

|||

| ||||||||||

|

|  MIL-PRF-62365C(AT)

b. A hydraulic test facility capable of permitting motor operation at all mounting

attitudes; continuous, intermittent, reversing and stalled operation in either

direction of rotating and application of loads on the motor shaft up to 30 lb-in.

c. Instrumentation necessary for measuring, motor rpm, motor torque, oil pressure,

oil flow rates, oil temperature, and leakage.

d. All gages and measuring devices shall be accurate within +5% of full scale.

4.3 First article inspection. First article inspection shall be performed on preproduction

or initial production samples as specified in table III (see 3.1).

4.3.1 Preproduction inspection. When specified (see 6.2), the preproduction sample

shall consist of two hydraulic motors. Preproduction inspection shall consist of examination as

specified in 4.4.1.3 and tests specified in table III.

4.3.2 Initial production inspection. Unless otherwise specified (see 6.2), the Government

shall select two samples, from the first 10 hydraulic motors produced under the production

contract for initial production inspection. Initial production units shall be examined as specified in

4.4.1.3 and tested as specified in table III.

4.4 Conformance inspection.

4.4.1 Sampling. Sampling for inspection lots and sampling for examination of

conformance, see 6.5.

4.4.2 Materials and design. Conformance to 3.2 thru 3.3.12 shall be determined by

inspection of contractor records providing proof of certification that materials and design conform

to requirements. Applicable records shall include drawings, specifications, design data, receiving

inspection records, processing and quality control standards, vendor catalogs and certifications,

industry standards, test reports, and rating data.

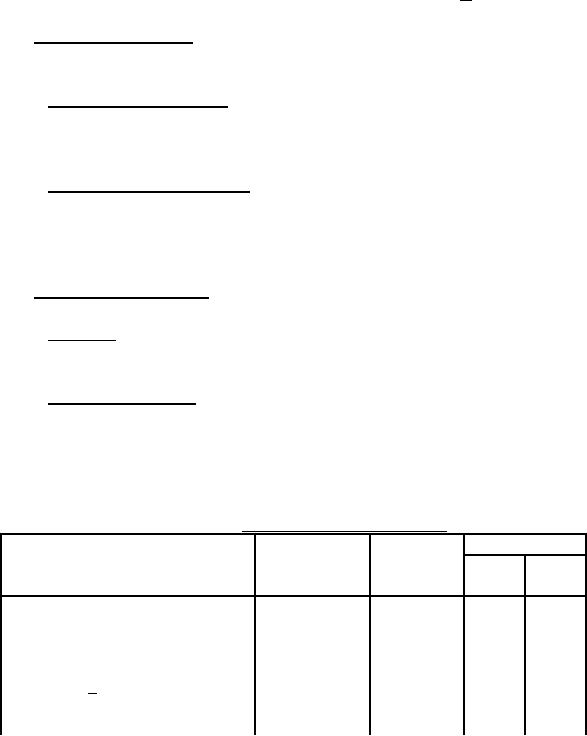

TABLE III. Classification of inspections.

Conformance

First

Test

Title

Requirement

Inspection

article 100%

4.4.1.3

X

Materials and finish

3.2 thru 3.2.4

Design and construction

3.3 thru 3.3.12

X

3.3.1

4.4.1.3

X

X

Fluid

3.3.2

4.2.4

Cleanliness 1/

3.3.3

4.4.1.3

X

3.3.8

4.4.1.3

X

Lubrication

4.5.1

X

Interchangeability

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |