|

|||

|

|

|||

| ||||||||||

|

|  MIL-R-81202D(AS)

Sampling test items.

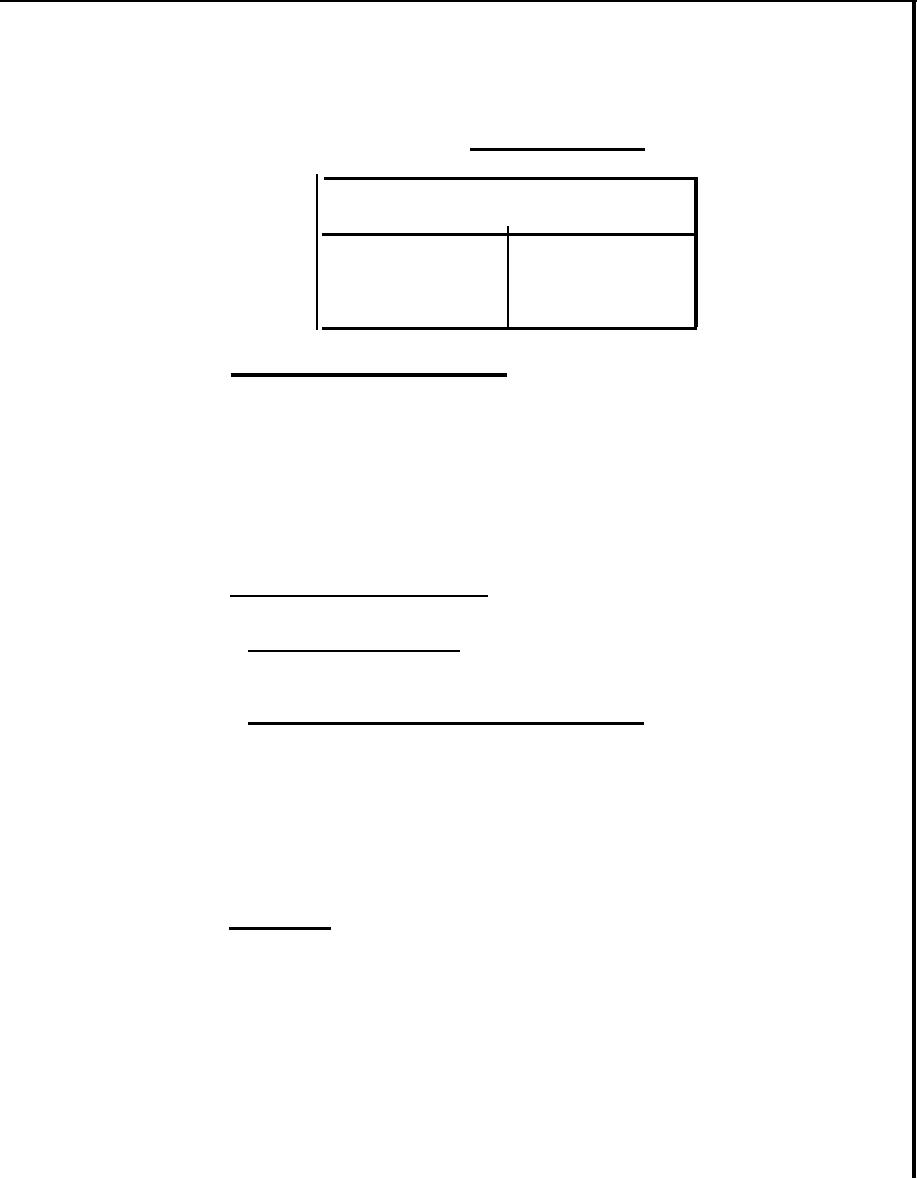

TABLE IV.

Number of samples

Lot size

to be tested

4

499 or less

4 plus 1 for each

500 or more

additional 500 or

fraction thereof.

4.6.2 Permanent volumetric expansion. The nitrogen receiver shall be pres-

surized hydrostatically to 5500 +/-100 psig and the total volumetric expansion

shall be determined. The pressure shall then be reduced to atmospheric and the

permanent volumetric expansion determined. The percentage of permanent volu-

metric expansion shall not exceed 5 percent of the total volumetric expansion.

Test values for all parameters shall be prepared for review by the procuring

activity. The nitrogen receiver shall be tested without its subassemblies in-

stalled. All open ports shall be sealed and a pressurization fitting in-

stalled. Testing may be conducted in any attitude. This test will not be per-

formed by the Government-approved test laboratory unless directed by the pro-

curing activity (see 6.2.1).

The receiver assembly shall be in-

4.6.3 Inspection-receiver assembly.

spected as follows:

4.6.3.1 Individual tests-visual. The receiver assembly shall be inspected

to ensure that it has been properly assembled and adjusted, and that the

workmanship is as specified herein.

4.6.3.2 First article and quality conformance tests.

a.

The receiver assembly shall be thoroughly examined to determine

conformance to all the requirements of the drawings listed on

DL 58A164D556 and this specification. Prior to performing the

cleanliness test, only external dimensioning shall be per-

formed.

The receiver assembly shall be examined to ascertain that the

b.

packaging, packing and marking is in accordance with Section 5.

4.6.4 Cleanliness. The receiver assembly shall be pressurized through the

charging valve to 2000 +/-50 psig with nitrogen gas (see 3.6). Initial back

ground contamination levels of the test gas shall be recorded. These levels

15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |