|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-20517H (AR)

4.5.2.2 Diametrical. The test method and the length of the

tubes shall be as specified in 4.5.2.1. The load shall be applied

by parallel flat plates in a direction perpendicular to the axis of

the tubes. Spherical seats are not required. Observation shall be

made for compliance with the applicable drawing requirement.

4.5.3 Determination of ingredients. (See 4.5.1 for replicate

determinations and 6.7 for equivalent test methods).

4.5.3.1 Delay composition.

(Barium Chromate, Boron) - In lieu

of making an analysis of each batch of delay compositions, as

applicable, a batch record shall be prepared for each batch produced

for production use. This batch record shall be used to demonstrate

the actual amounts of each ingredient used to make the batch as

specified on the applicable drawing. In additon to recording

composition of the batch, the batch record shall also be used to

record any control curing time for mixtures as necessary prior to

loading. A batch of composition shall be the amount of composition

used during a single work shift by a single employee or crew. The

batch may contain one or more mixes. When more than one mix is used

in a batch, the exact proportion of ingredients shall be measured

into each mix.

(Black Powder, Aluminum Powder)

4.5.3.2 Flash powder.

4.5.3.2.1 procedure. Transfer an accurately weighed portion of

approximately 2 g. of the flash powder that was dried for the

moisture determination to a tared crucible. Wash the sample between

10 and 15 times with 5 milliliters (mL.) portions of cold carbon

disulfide and rinse with ether. Continue washing the sample with

fifteen, 20 mL. portions of cold distilled water, allowing each wash

of the water to remain in contact with the sample approximately 1

minute before applying suction. Aspirate the crucible and contents

thoroughly, and dry in an oven maintained at a temperature of 100 +

5C. The crucible and contents shall be cooled in a desiccator

and weighed. To the contents remaining in the crucible add several

portions of hot dilute hydrochloric acid until the reaction

subsides. After all reaction has ceased, wash the residue with

several portions of hot water. Dry the crucible and contents in the

100 + 5C oven and then cool in a desiccator and weigh. Calculate

the percent of aluminum as follows:

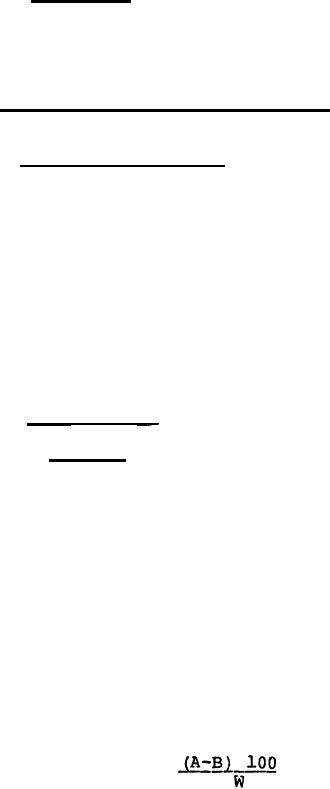

Percent aluminum =

where:

A = weight of

crucible and contents after the carbon disulfide

and water

extraction, g.

B = weight of

crucible and contents after the acid extraction,

g.

w = weight of

the sample, g.

35

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |