|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-4040F

4.5.3 Failures. One or more failures shall be cause for refusal to grant first article approval.

4.6 Conformance inspection.

4.6.1 Inspection lot. An inspection lot shall consist of one week's production of solenoids of the same design,

materials, and production processes, produced under essentially the same conditions and offered for inspection at

one time. Where production is less than 200 solenoids per week, a lot shall consist of two consecutive weeks

production. The date code shall indicate that the solenoids were produced during the first week.

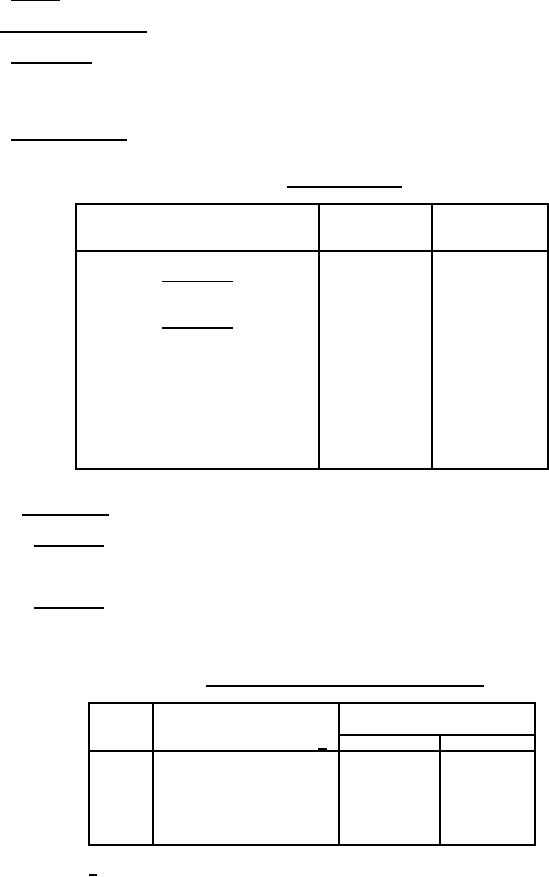

4.6.2 Group A inspection. The group A inspection shall consist of the inspection specified in table III, in the order

shown.

TABLE III. Group A inspection.

Inspection

Requirement

Method

paragraph

paragraph

Subgroup 1

Dielectric withstanding voltage

3.5.3

4.7.4

Subgroup 2

DC coil resistance

3.5.1.6

4.7.2.6

Coil current

3.5.1.5

4.7.2.5

Compensated actuating voltage

3.5.1.2

4.7.2.2

Insulation resistance

3.5.2

4.7.3

Visual and mechanical examination

3.1, 3.4, 3.5,

4.7.1

3.8, and 3.9

Deactuating voltage (when specified)

3.5.1.3

4.7.2.3

Operate and release time (when

3.5.1.4

4.7.2.4

specified)

4.6.2.1 Sampling plan.

4.6.2.1.1 Subgroup 1. All solenoids offered for inspection shall be subjected to the dielectric withstanding voltage

test. Lots having more than five percent total rejects shall not be furnished on the contract. Solenoids out of

specification limits shall not be shipped with the lot.

4.6.2.1.2 Subgroup 2. A sample of parts shall be randomly selected in accordance with table IV. If one or more

defects are found, the lot shall be rescreened and the defective parts removed. A new sample of parts shall then be

randomly selected in accordance with table IV. If one or more defects are found in the second sample, the lot shall

be rejected and shall not be supplied to this specification.

TABLE IV. Group A, subgroup 2 inspection sampling plan.

Visual and mechanical

Lot size

Electrical characteristics

inspection

(number of sample units) 1/

Major

Minor

2- 8

all

100 percent

3

9 - 15

all

13

3

16 - 25

20

13

3

26 - 50

20

13

5

51 - 90

20

13

6

1/ Electrical characteristics shall include coil resistance, coil current, and

compensating actuating voltage.

8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |