|

|||

|

Page Title:

Table II. Classification of defects. |

|

||

| ||||||||||

|

|  MIL-S-45387B(AT)

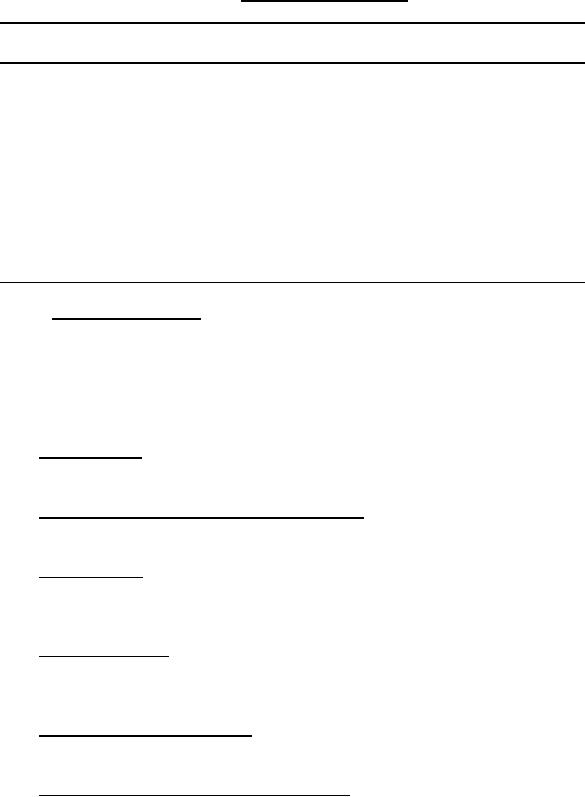

Table II. Classification of defects.

Categories

Minor AQL 4.0 Percent

Method of

Defective

Inspection

200.

Length of teeth

..................

SIE

201.

Chamfer (both ends)

..................

SIE

202.

Overall length

..................

SIE

203.

Threads requirements

..................

Go thread plug

Gage, not go

thread plug gage

204. Removed tooth

..................

Visual

mark (both ends)

205. Incomplete coverage

..................

Visual

206. Printing incomplete

..................

Visual

207. Damaged

..................

Visual

*

4.3.3.3 Inspection equipment. The inspection equipment for various characteristics specified

in 4.3.3.2 are referenced in the method of Inspection on the representative Supplementary Quality

Assurance Provisions (SQAP's) developed for each of the torsion bars tabulated on K8668989 spring

torsion bar suspension or other applicable drawings.

4.4 Inspection procedure.

4.4.1 Material check. To determine conformance to 3.3 and 3.3.1, prior to processing the

torsion bar springs the material shall be checked for specified defects and lengths.

4.4.2 Chemical composition and hardenability check. Unless otherwise specified chemical

analysis shall be performed to determine conformance to 3.3.2 and 3.3.3.

4.4.3 Forming check. To determine conformance to 3.5.1, the formed ends shall be checked

for proper lengths, diameter, and radius. After the serrations have been completed a dimensional

check shall be made of the serrations.

4.4.4 Heat treatment test. To determine conformance to 3.5.2 and 3.5.2.1, the torsion bar

springs shall be checked for Rockwell C hardness and the procedure shall be observed for

conformance.

4.4.5 Straightening operations check. To determine conformance to 3.5.3, the straightening

operation shall be checked for proper temperature.

*

4.4.6 Surface indications and discontinuities check. To determine conformance to 3.5.4, the

torsion bar springs shall be checked for discontinuities in accordance with Specification

MIL-M-11472, 100 percent. If springs are fabricated from non-magnetic material, they shall be

inspected by the dye penetrant method of MIL-I-6866, or by an approved alternate method.

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |