|

|||

|

Page Title:

Military-Commercial Connections |

|

||

| ||||||||||

|

|  MIL-S-46777C

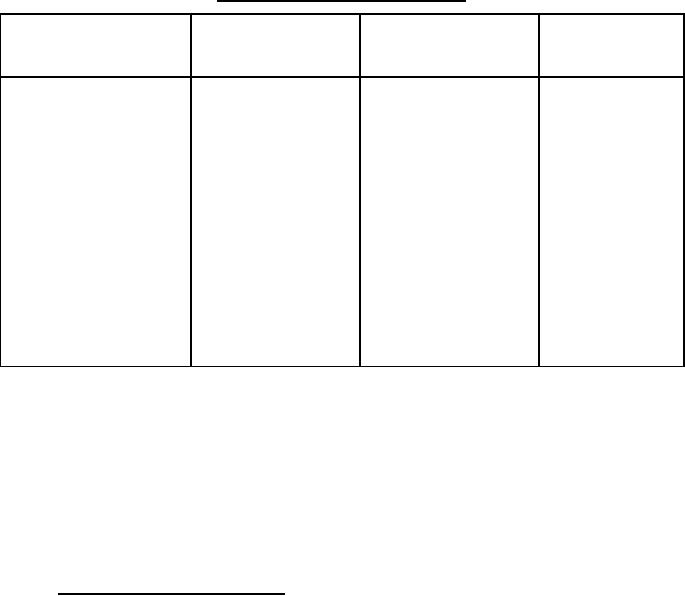

Military-Commercial Connections

Connection

Comm. TTMA

Mil. Receptacle

Terminal

(Circuit No.)

Instructions

Wiring Ident

Function

-

None.

A

Blackout Marker

Connect to

B (22 461)

Ser. Left Turn & Stop

YEL (3)

-

None.

C

Blackout Marker

Connect to

D (90)

Ground

WHT (1)

Connect to -

E (21 489)

Ser. Tail & Marker

BLK (2)

& Connect to

BRN (6)

-

None.

F

Blackout Stop

None.

H

Blackout Marker

-

Connect to

J (22 460)

Ser. Right Turn & Stop

GRN (5)

None

K (37)

Aux. Power (Hot)

BLU (7)

Ground to Frame

L (90)

Ground

-

None.

M

Electric Brake

-

None.

N

Electric Brake

-

With the military system installed, the TTMA marker circuits, color coded BLK (2) and

BRN (6), shall be electrically isolated from each other, thus preventing 12-volt current cross-

over when operated by commercial trucks through the 12-volt TTMA plug. Replaceable diodes

may be used, having a minimum amperage of 150 percent of the current demand of the running

lamps served. Military circuits, letter coded B (461) and J (460) on the tactical trucks, are

passenger car combination stop and turn signal type, using the same lamp filament, and there is

no single stop lamp circuit. As a result, the trailer's turn signal lamp circuits, YEL (3) and

GRN (5), shall function as both turn signal lamps and stop lamps and the trailer's normal stop

circuit, RED (4), cannot be energized from the military truck's 24-volt system input.

3.11 Fungus and moisture resistance. The electrical circuitry of all electrical systems,

including all components and connections except as specified below, shall be protected from the

effects of moisture and fungus growth by an overall treatment with commercial electrical

varnish:

(a)

Components or circuit elements which are inherently fungus and moisture resistant

or which are hermetically sealed need not be treated.

(b)

Components or circuit elements whose functions will be adversely affected by the

varnish coating shall not be treated.

When used, the varnish shall be applied by spray, brush, or a combination of both to give a

minimum dry-film thickness of 1 mil to component or element surfaces previously cleaned and

prepared so that the surfaces are free from all foreign matter which would interfere with the

adherence or function of the varnish.

35

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |