|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-55257C(CR)

skids) shall be raised 18 inches and the shelter shall be allowed to fall

freely onto a hard substantial concrete surface. This inpact shall be

performed four times, once for each bottom edge of the shelter. On com-

pletion of these drops, the shelter assemblage shall meet the require-

ments of 3.16.

4.9 Air tightness test. The shelter facility when subjected to the

following test, shall meet the requirements of 3.16.

a. The air tightness shall be tested by introducing clean dry

air into the closed shelter through an existing appropriate opening (i.e.

drain fixture) to create an internal air pressure that exceeds the exter-

nal pressure by a minimum of six (6) inches of water.

b. A manometer graduated in 0.1 inches or less shall be uti-

lized to measure this differential pressure.

c. The test apparatus shall include an air supply sufficient to

maintain the required air pressure, an air flow regulator and an input

air pressure gage.

d. The shelter facility shall be tested for air tightness by

painting the sealed joints, seams, rivets, etc. of the external modi-

fications with Leak-Tat Formula 372 (American gas & Chemicals, Inc.,

Leak-Tat Division) or equal soap and water solution.

e. To minimize air loss, temporary seals, shims and tape are

permitted to seal the shelter door, blower cover and air conditioner port

openings not being tested.

4.10 Mounting insert tests. Four of each size inserts shall be

randomly selected for test. Each insert shall be tested with an axial

load followed by a torque load in accordance with Table V. After test,

the requirements of 3.19 shall be met. Failure of any insert shall be

cause for rejection of the sample equipment. This test shall be conduct-

ed prior to installation of brackets, racks, etc.

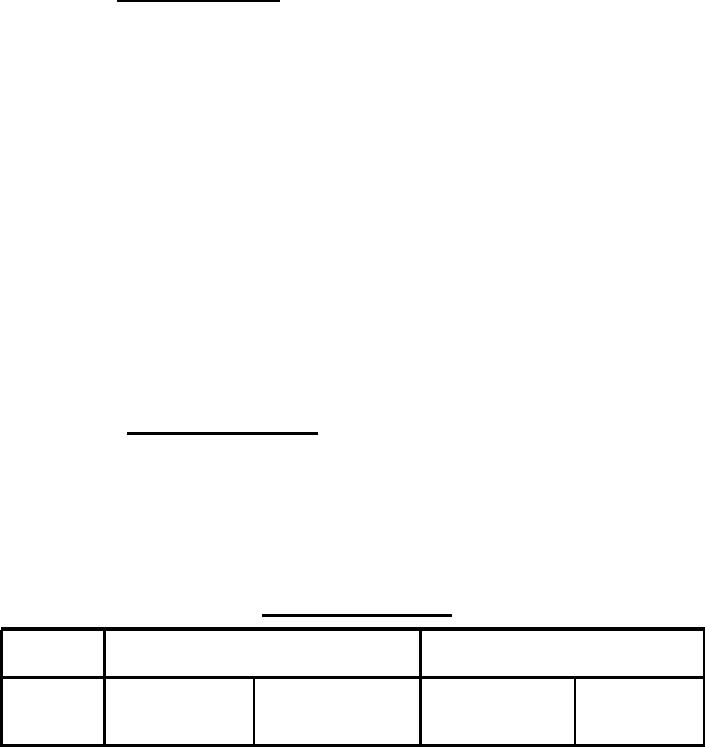

TABLE V

Mounting insert loads

Group B Test

First Article and Group C Test

Insert

Axial (Lbs) Torque (Inch lbs)

Axial (lbs) Torque (Inch Lbs)

Size

23

300

23

0-32

600

I

60

650

60

1/4-20

1300

100

1000

100

2000

5/16-18

20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |