|

|||

|

Page Title:

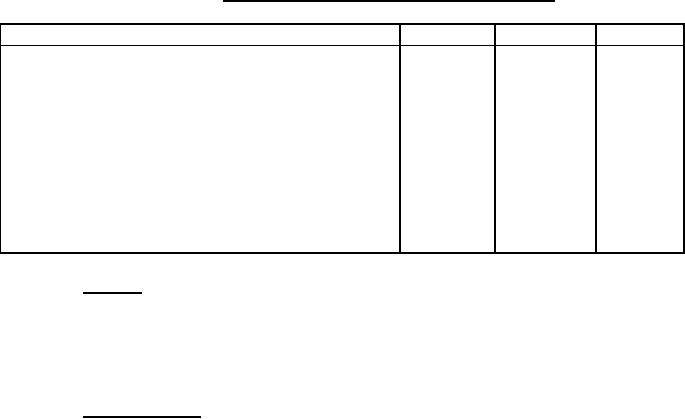

Table III. Semitrailer chassis dimensions and clearances. |

|

||

| ||||||||||

|

|  MIL-S-62076B(AT)

without splices or joints. Where frame members are spliced on gooseneck chassis, joints shall be

reinforced to fulfill the dynamic loading requirements of 3.3.1. Splices shall be designed to

avoid stress concentration. Splice welds shall be continuous. The frame shall support the weight

of the fully loaded container(s) specified in table II. Model A, B and C semitrailer chassis shall

have the dimensions and clearances specified in table III. Container-chassis interface shall be in

accordance with ANSI MH5.6-1978.

TABLE III. Semitrailer chassis dimensions and clearances.

Description

Model A

Model B

Model C

14

14

Ground clearance (minimum), inches

14

Upper fifth wheel height, from ground to

underside of upper fifth wheel plate, inches,

48

48

plus or minus one inch

48

Distance from vertical centerline of kingpin

to front end of semitrailer (minimum),

36

36

inches

18

Swing radius from vertical centerline of kingpin

to most difficult point of semitrailer nose

60

60

(maximum), inches

60

3.4.1.1 Bolsters. The semitrailer chassis frame shall include full-width, steel front and rear

bolsters. Model C semitrailer chassis shall, in addition, include a mid-center, full-width, steel

bolster. Rear bolsters may serve as rear crossmembers. Twist lock and pin lock devices

specified in 3.4.1.2 shall be installed at the bolster ends. Bolsters shall be reinforced as

necessary in accordance with manufacturer's standard commercial practice.

3.4.1.2 Locking devices. The semitrailer chassis shall be equipped with twist-lock devices

on the frame bolsters to engage and secure the lower corner fittings of the container(s). Model A

and B chassis shall be provided with four twist-lock devices, one at each corner of the frame

front and rear bolsters, or with two pin-lock devices on the front bolster of the frame and with

two twist-lock devices on the rear bolster of the frame. Model C chassis shall be provided with

four twist-lock devices, one at each corner of the frame front and rear bolsters and with four

retractable twist-lock devices at the mid-center bolster for securing two 20 foot containers. The

locking devices shall be designed to preclude unintentional release. The locking devices and

their locations shall be in accordance with ANSI MH5.6-1978, and the devices shall meet the

requirements of Federal Motor Carrier Safety Regulation 393.100(e).

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |