|

|||

|

Page Title:

Non-Arming of safe and arming subassembly |

|

||

| ||||||||||

|

|  MIL-S-63383(AR)

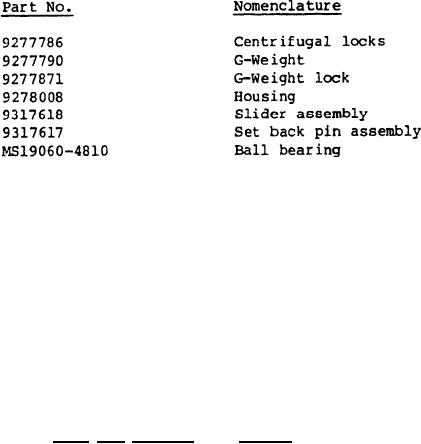

Also included are all associated springs, locks and closures for

the above assembly.

Optional parts are:

Closure firing pin, Part No. 9317591

Rear locks, Part No. 9278057

Slider, lock, Part No. 9278060

Rear lock springs, Part No. 9278109

And all associated closures.

Also included for the optional parts are all associated springs,

locks and closures for the above assembly.

The test sample must not contain the staked disc closure, Part

No. 9277812 for this test.

The slider shall be maintained in the correctly oriented

position during the arming and non-arming tests. The Contractor,

when necessary, may utilize an interim slider lock for test purposes.

The S&A assembly shall be tested as follows using approved spin

and testing equipment.

The S&A, after secured nesting in the spin fixture, shall be

spun up to the arming speed specified on the applicable drawing.

To verify that the set back pin is in the non-armed position,

the contractor shall attempt to arm the "G" weight (Dwg 9277790), by

applying the minimum arming force as stated on the applicable

drawing. The S&A subassembly shall not arm. The force on the "G"

weight shall then be released,

The set back pin assembly, (Dwg 9317617), shall be moved to the

armed position and held in place. Arming force shall be as

specified in drawing 9317620.

17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |