|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-81054A(OS)

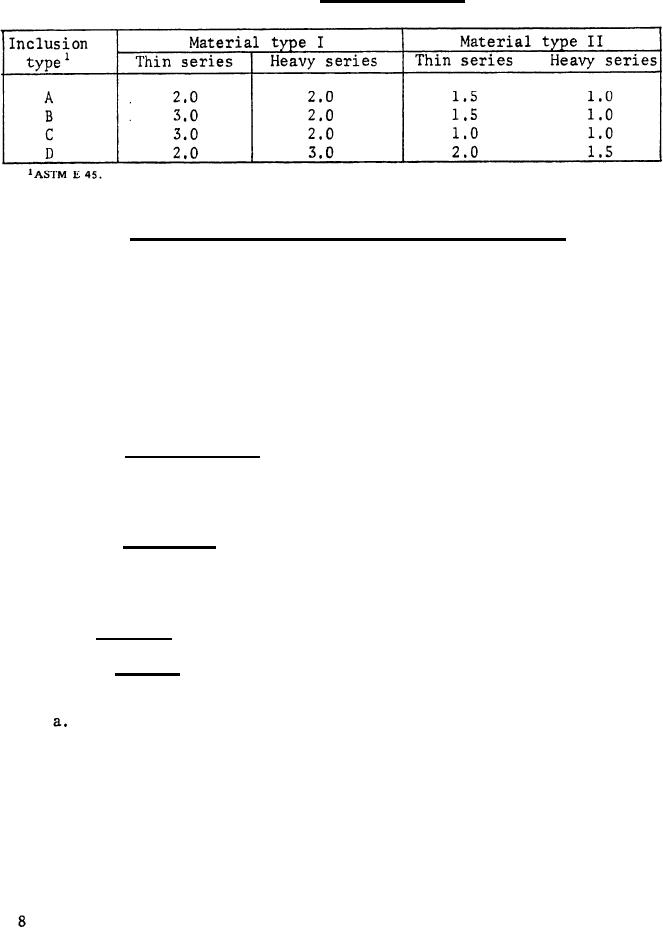

TABLE IV.

Inclusion rating.

3.3.1.9.3 Macroetch testing of bars, type I, composition B. Visual

examination of deep-acid-etched reforging stock in sizes up to and

including 36 square inches shall be equal to or better than S2R1C2;

sizes over 36 to and including 100 square inches shall be equal to or

better than S2R2C3 of ASTM E 381. Macroscopic examination of finished

bars is required only if the manufacturers inspection of the micro-

structure at an earlier stage of processing such as forged bars, blooms,

or billets has not been accomplished, Two or more billet slices at least

1/4 inch thick shall be selected to represent each heat of steel from

which material is submitted for acceptance.

3.3.1.10 Surface defects. The steel shall have no imperfections of

a nature or degree that will be detrimental to the stamping, forming,

machining, or fabrication of finished parts.

3.3.1.11 Tolerances. Unless otherwise specified, tolerances for bar

stock shall conform to AMS 2251. Tolerances for forgings shall be as

specified by the applicable engineering documents,

3.3.2 Forgings.

3.3.2.1 Process. Unless a specific process is designated, forgings

shall be formed by any of the following processes:

Smith (flat die)

Hammer die

b.

c.

press die

d.

Hot upset

Ring roll

e.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |