|

|||

|

Page Title:

Thermal effect on zero and sensitivity shift |

|

||

| ||||||||||

|

|  MIL-T-23588C(OS)

4.4.1.1 Vibration, nonoperating. The transducer s-hall be subjected to

the "Vibration, nonoperating" test of MIL-E-82590 and thereafter shall

meet the requirements of 3.5.1.1.

*

4.4.1.2 Vibration, operating. The transducer shall be subjected to the

"vibration, operating" test of MIL-E-82590 and during and thereafter shall

meet the requirements of 3.5.1.2.

4.4.2 Temperature and humidity

*

4.4.2.1 High temperature and humidity, nonoperating. The transducer

shall be subjected to the "High temperature and humidity, nonoperating"

test of MIL-E-82590

and thereafter shall meet the requirements of 3.5.2.1.

*

4.4.2.2 High temperaturem operating. The transducer shall be subjected

to the "High temperature, operating" test of MIL-E-82590 and, while at

the test temperature, shall meet the requirements of 3.5.2.2.

*

4.4.2.3 Low temperature, nonoperating. The transducer shall be sub-

jected to the Low temperature, nonoperating" test of MIL-E-82590 and

thereafter shall meet the requirements of 3.5.2.3.

*

4.4.2.4 Low temperature, operating . The transducer shall be subjected

to the "Low temperature, operating" test of MIL-E-82590 and, while at

the test temperature, shall meet the requirements of 3.5.2.4.

*

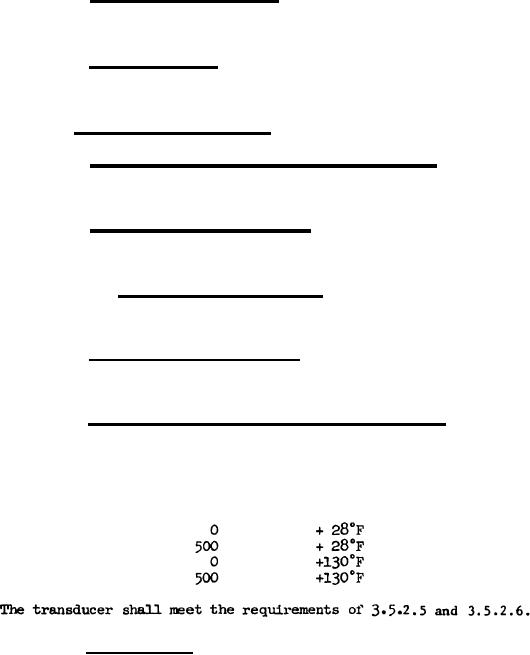

4.4.2.5 Thermal effect on zero and sensitivity shift. With 8 volts,

400 Hz applied, the transducer shall be placed within a test chamber

and subjected to the following temperatures and pressures for a period

of one hour at each temperature setting:

4.4.2.6 Thermal shock. With no pressure, 8 volts, 400 Hz applied to

the transducer, measure and record the output voltage. Prior to immer-

sion, ensure that the pressure tap of transducer is open and that the

cavity is filled with water at a differential temperature of 40 degrees F.

Completely submerge the transducer in water at a differential temperature

of 40 degrees F from that of the transducer, for a one minute period.

Measure and record the output voltage at 10, 20, 30, and 45 seconds, and

*

at one, two, three and five minutes after immersion. The transducer shall

meet the requirements of 3.5.2.7.

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |