|

|||

|

|

|||

| ||||||||||

|

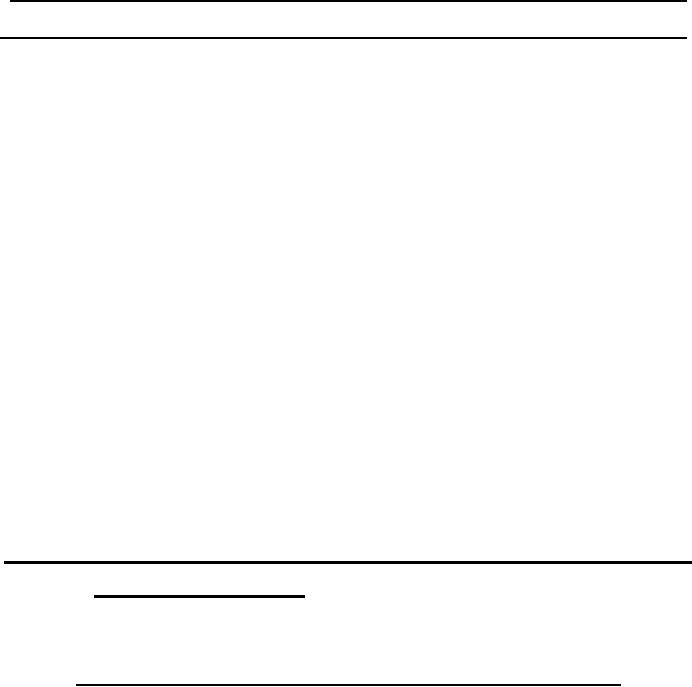

|  MIL-T-43694(GL)

Classification

Examine

Major

Minor

Defect

Thread (nylon)

X

Not type, class, or size specified

X

Color not as specified

Stitches and

X

Stitching pattern not as specified

stitching

X

Any row of stitching missing

One stitch per inch fewer than minimum

or more than maximum specified

X

Two or more stitches per inch fewer than

X

minimum or more than maximum specified

Thread breaks, bobbin runouts, skipped

X

stitches and runoffs

Ends of stitching not backstitched or

X

secured as specified

Tension loose resulting in loose top or

bottom thread, or tight tension causing

puckering of material at stitch line

X

Needle chews or bunched stitching

X

Construction

Any component missing, not assembled

and assembly

or joined as specified

X

Marking

Omitted, incorrect, illegible; location,

size or color not as specified

X

Workmanship

Grease, oil, ink smears, dirt or other

foreign matter; thread ends not trimmed

throughout

X

4.4.2.2 Dimensional examination. - The sample unit for this examination

shall be one assembly or component, as applicable. The examination shall be

made to determine compliance with dimensions specified on the drawings. Any

nonconformance shall constitute a defect.

4.4.3 Inspection levels and acceptable quality levels for examination. In-

spection levels and acceptable quality levels (AQLs), expressed in defects per

hundred units, shall be aS follows:

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |