|

|||

|

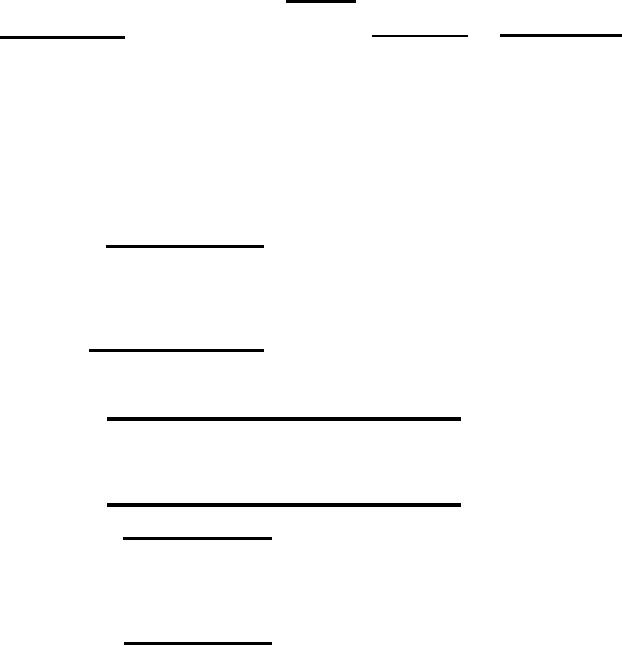

Page Title:

Government furnished inspection equipment |

|

||

| ||||||||||

|

|  MIL-T-46316B(MU)

TABLE II

TEST PROCEDURE

REQUIREMENT

CHARACTERISTIC

Certification

3.1

Fabrication

301.

Certification

3.2

General specification

302.

4.6.1.1

3.3.1

Temperature storage

303.

4.6.1.1

3.3.2

Temperature operating

304.

4.7.2.11

3.9.2

305.

Torque (Reticle lever (-40+150))

4.7.2.11

3.9.1

Torque (Cant correction knob

306.

(-40+150) )

4.7.2.11

3.9.3

307.

Torque (Mirror, plunger, arm and

rheostat (-40+150))

4.4.2 Failure of sample.- Should any one item of a special sampling

fail to meet the specified test requirements, acceptance of the represented

inspection lot will be suspended by the Government until necessary correc-

tions have been made by the contractor and the resubmitted samples have

been approved (see 4.3.3).

4.5 Inspection equipment.- Except as otherwise provided for by the

contract, the contractor shall supply and maintain inspection equipment

in accordance with the applicable requirements of MIL-I-45607.

4.5.1 Government furnished inspection equipment.- Where the contract

provided for Government furnished test equipment, supply and maintenance

of test equipment shall be in accordance with the applicable requirements

specified in MIL-I-45607.

4.5.2 Contractor furnished inspection equipment.

4.5.2.1 Government design.- Unless otherwise specified in the con-

tract, all inspection equipment specified by drawing number in specifica-

tion or SQAP forming a part of the contract shall be supplied by the con-

tractor in accordance with technical data listed in the List of Inspection

Documents when provided with the Technical Data Package (TDP).

4.5.2.2 Contractor design.- The contractor shall design and supply

inspection equipment compatible with the "Test Methods and Procedures"

specified in 4.6 of this specification and with the component inspection

procedures specified in "Examination" and "Test Facilities" requirements

of MIL-F-13926. Since tolerance of test equipment is normally considered

to be within 10% of the product tolerance for which it is intended, this

inherent error in the test equipment design must be considered as part

of the prescribed product tolerance limit. Thus, concept, construction,

materials, dimensions and tolerance used in the design of test equipment

shall be so selected and controlled as to insure that the test equipment

will reliably indicate acceptability of a product which does not exceed

90% of the prescribed tolerance limit, and permit positive rejection when

non-conforming. Construction shall be such as to facilitate routine

calibration of test equipment.

7.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |