|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-46590C

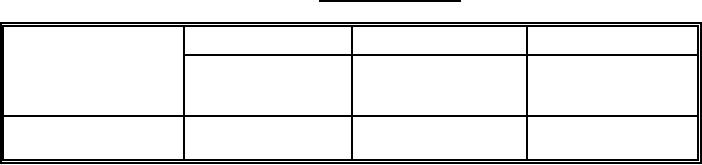

3.7.2.2 Ring nut. Torque requirements shall be as specified in table II. No movement or deformation

shall occur upon application of the breakaway torque.

TABLE II. Torque requirements.

A

B

C

Seating or Bottoming

Components

Run-on, minimum

(including A)

Breakaway, minimum

(inch pounds)

(inch pounds)

(inch pounds)

Ring nut, after assembly of

40

600 30

400

rod piston and spacer piston

3.7.3 Piston rod retraction. The piston rod shall not retract into the body upon application of a static

compression load of 25 5 pounds between mounting points.

3.7.4 Fluid leakage. The thruster shall not show evidence of fluid leakage when tested in Positions I and

II (see 3.7.4.1 and 3.7.4.2) for a minimum of 12 hours each prior to the installation of the reservoir assembly.

3.7.4.1 Position I. Thruster shall not show evidence of fluid leakage at the orifice hole when the thruster

is horizontal and the orifice hole pointing down.

3.7.4.2 Position II. Thruster shall not show evidence of fluid leakage at the piston when the thruster is

vertical with the piston pointing down.

3.8 Protective finish. Protective finish shall be in accordance with the applicable specifications and shall

apply to all surfaces of the component regardless of contour configuration.

3.9 Residual magnetism. The metal parts assembly shall not deflect the indicator of the compass more

than five degrees in either direction using procedures in 4.6.9.

3.10 Workmanship. Thrusters shall be free of cracks, splits, or other defects which might prevent proper

mating with connecting parts or proper functioning of the device.

3.10.1 Metal defects. All components shall be free from cracks, splits, cold shuts, inclusions, porosity,

or any similar defect.

3.10.2 Burr. No part shall have a burr which might interfere with the assembly or function of the item

or which might be injurious to personnel handling the item.

3.10.3 Foreign matter. No part or assembly shall contain chips, dirt, grease, rust, corrosion, or other

foreign matter.

4. QUALITY ASSURANCE PROVISIONS

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |