|

|||

|

Page Title:

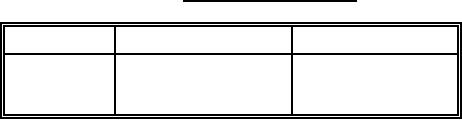

Table II. Conditioning temperature |

|

||

| ||||||||||

|

|  MIL-T-46604B

4.2.3.3.1 Ballistics. Twenty-one units shall be tested to determine compliance with 3.6. The units shall

be temperature conditioned as provided in table II and 4.3.4.2. Failure of any unit to comply with 3.6.1

through 3.6.5 shall be cause for rejection of the lot.

TABLE II. Conditioning temperature.

Sample size

Method

Temperature (F)

7

Load (see 3.6.1)

65 to 70

7

Load (see 3.6.1)

65 to 75

7

Load (see 3.6.1)

195 to 200

4.2.3.3.2 Retest. There shall be no retests.

4.2.3.3.3 Test failure. If a test failure is attributable to an assignable cause, excluding the test thruster,

the original test results shall be discarded and that test reconducted.

4.3 Test methods and procedures.

4.3.1 Breakaway torque. A torque wrench, set at the torque requirements specified in table I, shall be

used with an appropriate adapter to determine the adequacy of the joint. The breakaway torque shall be

applied to the base cap.

4.3.2 Residual magnetism. The assembly shall be tested for excessive residual magnetism using an

approved compass in an area free of local magnetic effects by placing the assembly 5 inches from the end at

the same height as the compass, in the north-south horizontal position (head end at south) with the compass

set in an east-west heading. The assembly shall be moved at a speed no greater than 10 feet per minute past

the compass for its entire length, rotated 90 degrees in the horizontal position about its longitudinal axis, and

moved slowly back past the compass. This procedure shall be repeated for each 90 degree rotation of the

assembly for four full passes.

4.3.3 Radiographic examination. All assembled thrusters shall be radiographically examined in

accordance with MIL-STD-453, with the exception that an thruster assembly will be used for the penetrameter.

Any observable imperfections in components or assembly shall be cause for rejection. The thrusters shall be

positioned for the most revealing exposure, with the long axis of each assembly perpendicular to the rays of

the X-ray machine. All thrusters shall be identified with serial numbers prior to X-ray examination. The serial

numbers shall be in consecutive order beginning with the number 001 in each production lot. Any missing

numbers are to be identified on the X-rays. The thrusters shall be arranged on trays or boards in consecutive

numerical order, and each radiograph shall carry a permanent identification of the units displayed thereon.

The radiographic plate identification shall include item nomenclature, the complete lot number, the span of

serial numbers displayed, and the contract number. The radiographs of the entire production lot shall

accompany the ballistic sample to the activity conducting the production lot acceptance test. Defective

thrusters found during X-ray review are to be marked on the X-ray prior to shipment and those defective items

shall be removed from the production lot. Film interpretation of the radiographs shall verify the presence and

correct positioning of the following parts:

8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |