|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-46605B

3.4 Hydrostatic pressure. The body shall withstand a hydrostatic pressure of 11,500 pounds per square

inch (psi) for 15 seconds, minimum, without leaking, deformation, or mechanical failure (see 6.4.1).

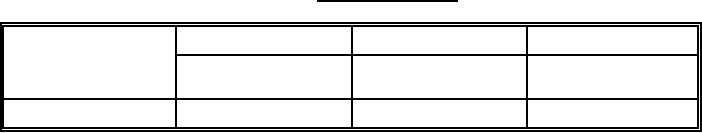

3.5 Torque. Torque requirements shall be as specified in table I. No movement or deformation shall

occur upon application of the breakaway torque.

TABLE I. Torque requirements.

A

B

C

Seating or Bottoming,

Component

Run on (minimum)

Including A (inch pounds)

Breakaway (inch pounds)

Piston and piston fastener

--

150 20

75 minimum

3.5.1 Piston rotation. Upon completion of assembly, the piston fastener shall be free to rotate 360

degrees in a clockwise direction.

3.6 Shear pin strength. The shear pin, after application of protective finish, shall shear when a load of

41 5 pounds is applied at the steady rate of 0.125 inch per minute.

3.7 Metal parts assembly. Parts shall be combined to produce an assembly which conforms to the

requirements of the metal parts assembly drawing.

3.8 Protective finish. Protective finish shall be in accordance with the applicable specifications and shall

apply to all surfaces of the component regardless of contour configuration.

3.9 Residual magnetism. The metal parts assembly shall not deflect the indicator of the compass more

than five degrees in either direction using procedures in 4.6.6.

3.10 Workmanship. Thrusters shall be free of cracks, splits, or other defects which might prevent proper

mating with connecting parts or proper functioning of the device.

3.10.1 Metal defects. All components shall be free from cracks, splits, cold shuts, inclusions, porosity,

or any similar defect.

3.10.2 Burr. No part shall have a burr which might interfere with the assembly or function of the item

or which might be injurious to personnel handling the item.

3.10.3 Foreign matter. No part or assembly shall contain chips, dirt, grease, rust, corrosion, or other

foreign matter.

4. QUALITY ASSURANCE PROVISIONS

4.1 Responsibility for inspection. Unless otherwise specified in the contract or purchase order, the

contractor is responsible for the performance of all inspection requirements (examinations and tests) as

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |