|

|||

|

Page Title:

Table III. Means of attaching filler necks to fuel tanks |

|

||

| ||||||||||

|

|  MIL-T-46786B

3.5.2.1 Filler caps. The filler cap shall be constructed of either

material treated to resist corrosion or material inherently corrosion

resistant. The cap shall be captive chained or cabled to the strainer, when

provided, or to the tank, to prevent loss of the cap. The chain or cable shall

include a swivel joint and shall permit unobstructive refueling of the tank.

The captive cap components shall inherently resist corrosion and deterioration.

3.5.2.2 Filler neck. Filler necks shall be constructed of materials

treated to resist corrosion, compatible with the fuel tank, and shall be

affixed to the fuel tank in a manner compatible with the type of fuel tank

construction (see table III).

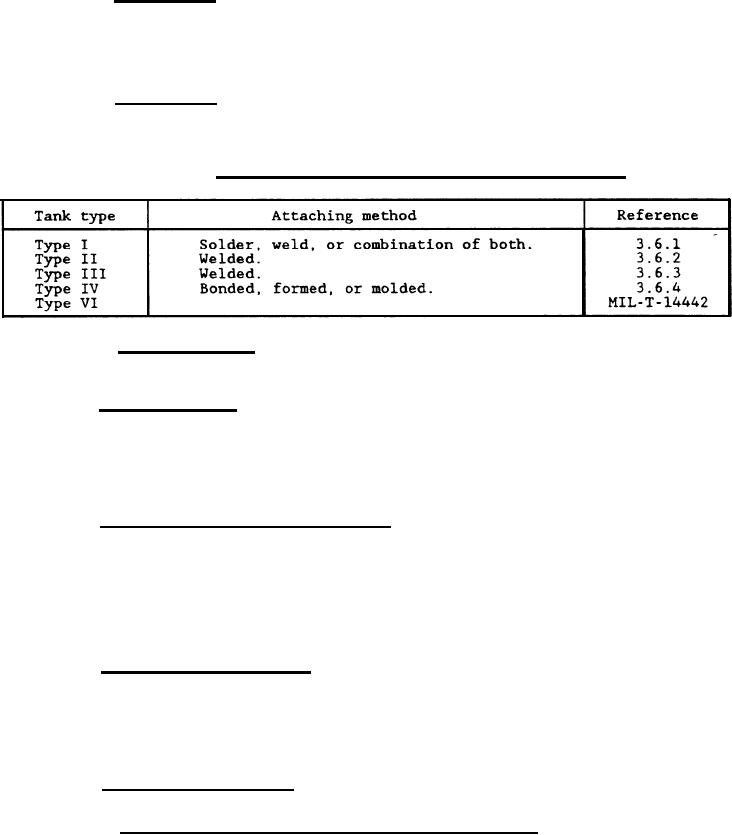

TABLE III.

Means of attaching filler necks to fuel tanks.

3.5.2.3 Filler strainer. Filler strainers shall be removable, constructed

of noncorrosive materials, 60-mesh screen, and shall be protected to prevent

damage caused by contact with the refueling nozzle.

3.5.3 Fuel tank drain. Fuel tanks shall be provided with a drain

connection separated from the fuel supply line and shall be of sufficient size

and located to permit complete drainage of condensation, contaminants, and

fuel. Unless otherwise specified herein, the drain connection shall be a

leakproof, threaded plug. When specified (see 6.2), a leakproof drain valve,

stopcock, or ball check release valve shall be acceptable. Drains or other

bottom fittings shall be protected against damage from impact.

3.5.4 Auxiliary fuel supply connection. When specified (see 6.2), an

auxiliary, 3-way, sealed, plug-type, selector valve, labeled "FUEL SUPPLY",

shall be provided with Provisions to accept a 5/16-inch, standard, flared

fitting conforming to SAE J512. A protective cap secured against-loss shall be

provided with the fitting. A corrosion-resistant circular faceplate shall be

mounted on the fuel selector valve and shall be marked with a double-ended

arrow indicating direction of rotation and labeled "OFF", "UNIT TANK", and

"AUXILIARY". A balance line shall be included when multiple tanks are

furnished.

3.5.5 Fuel line shutoff valve. When specified (see 6.2), a fuel line

shutoff valve shall be provided and shall be attached directly to the fuel tank

permitting removal of the tank prior to draining. The shutoff valve shall be

constructed of noncorrosive materials compatible with the fuel tank and the

fuel supply line. The valve shall be labeled "FUEL SHUTOFF". The valve shall

be provided with double-ended arrows showing direction of operations and

labeled at each end to indicate functional result (e.g., open and off).

3.5.6 Fuel measuring device. When specified (see 6.2), the fuel tank shall

be equipped with a fuel measuring device as specified herein.

3.5.6.1 Fuel liquid quantitv transmitter and indicator. When specified (see

6.2), a liquid quantity fuel transmitter shall be furnished and installed. The

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |