|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-50009A

108

Bags, wooden or metal containers

in the solvent to such a depth that the tops

closure incorrect.

of the vanes are 3 centimeters (cm) below

Strapping of wooden containers loose

109

the surface. Start the stirrer, adj ust the tem-

or missing.

perature to 77 2F., and maintain the

Mixing instruction incorrectly pack-

110

temperature throughout the test. Add 8.0

aged, missing, or improperly locat-

ed in or on container.

0.1 g of the specimen, Record the time of ad-

111

Marking incorrect, missing, or il-

dition of the sample and the time at which

legible.

the gel covers a mark on the stirrer shaft

Minor.

AQL 4.0 percent defective,

201

1 cm below the initial liquid level. Record

Packing arrangement in wooden con-

tainers incorrect.

the time elapsed as vortex time.

4.5 Tests. Distilled water and analytical

4.5.2 Gel consistency.

grade chemicals shall be used throughout the

tests. Where applicable blank determinations

4.5.2.1 Procedure. All gels shall be pre-

shall be run and corrections applied where

pared in duplicate for each specimen, using

significant.

the equipment specified in 4.5.1.1, and test

solvent conforming to MS602. The solution

4.5.1 Gel formation.

temperature during stirring shall be main-

tained at 77 2F. The amounts of speci-

4.5.1.1 Equipment. The equipment re-

men and test solvent shall conform to table

quired for preparing gels for test purposes

II.

shall consist essentially of the following:

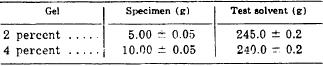

TABLE II. Gel formu lae for consistency test

(a) A mechanical stirrer rotating at a

speed of 300 10 revolutions per

minute (rpm). The stirrer shall

be fabricated of a glass or corro-

sion-resistant metal rod, 3/8 inch

in diameter, with four vanes of

The gels shall be stored in glass jars or in

the same material as the rod, 7/8

s t o r a g e tubes manufactured from steel,

by 7/8 by 1/8 inch, set at right

stainless steel, or anodized aluminum, for a

angles and with the faces parallel

period of 24 4 hours at the applicable

to the axis of the rod.

temperature specified in 3.3. At the end of

(b) A square, pint-size, mason-type jar

the storage period each gel shall be tested

approximately 3 by 3 by 5 inches.

for consistency in accordance with method

100 of Specification JAN-I-711, except that

(c) Storage containers of the type de-

in testing the 2 percent gel and 4 percent gel

scribed in method 100 of Specifi-

the load shall be reduced by 25 g instead of

cation JAN-I-711.

50 g and one conditioning stroke shall be

( d ) Constant temperature baths (air

used instead of the five called for in method

or liquid) capable of maintaining

100.

the specified test temperatures.

( e ) A weighing room maintained at

77 2F. and a maximum rela-

4.5.2.2.1 Two percent gels. Results of con-

tive humidity of 50 percent.

sistency tests on 2 percent gels within each

4.5.1.2 Procedure. Place 192.0 0.2 g of

set of duplicates shall agree within 25 g.

test solvent conforming to Standard MS602

Tests shall be repeated until this condition is

met, using fresh gel preparations.

into the glass jar and immerse the stirrer

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |