|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-62357A

capable of accepting a 100 psi air pressure test for at least 5 minutes without leakage. The fitting

gasket shall be capable of service in minus 20oF to plus 180oF without evidence of deformation or

change in dimensions. Gaskets on type I trailers shall conform to 3.1.1.4.

3.9.6 Pump. An engine driven, self-priming centrifugal pump shall be provided. Pump

materials shall be corrosion resistant. The suction intake and pressure discharge ports of the

pump shall be not less than 1.500 inches in diameter. A check valve shall be provided in the

pump. A line strainer shall be furnished at the suction port of the pump. The line strainer shall be

capable of removing any contamination, dirt and debris that would interfere with the pump

operation. Drains in the system shall be provided to allow drainage of liquid(s) from the complete

system. An instruction plate for the pump, the engine and the plumbing system operations shall be

provided and shall be secured on the inside cabinet door.

3.9.7 Pump performance. The pump shall be capable of loading and unloading the tank body

with liquid. The pump shall be capable of lifting the specified liquid(s) from 15 feet below ground

level through the length of 1.500 inch hose specified in table III into the suction port of the pump.

The rate of flow under these conditions shall be not less than the suction flow rate specified in

table III. The pump shall be capable of discharging the specified liquid(s) from the tank, against

the discharge head specified in table III, at the discharge flow rate specified in

table III.

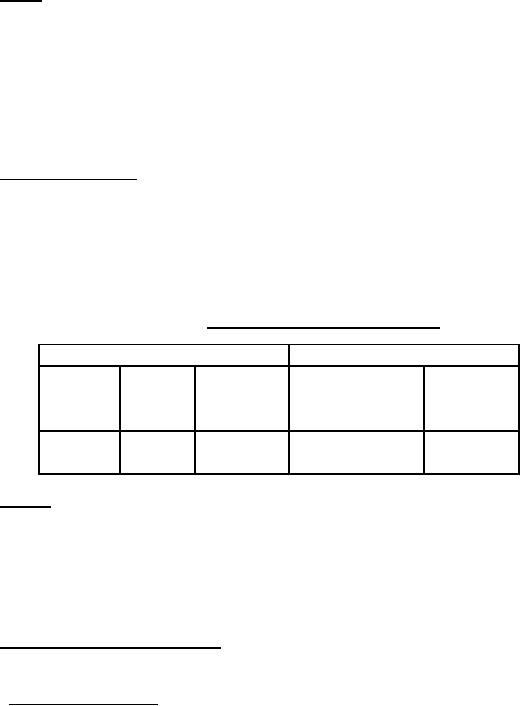

TABLE III. Pump performance requirements.

Suction

Discharge

Head

Trailer

Length

Flow rate

ft. of water

Flow rate

type

of hose

(gpm)

(pressure psi)

(gpm)

I

25

40

81 (35)

35

II

100

30

104 (45)

100

* 3.9.8 Engine. An air cooled, four cycle, diesel engine shall be provided to drive the pump.

The engine shall have a manual cranking system. The engine and pump shall be mounted to a

common bedplate and shall be secured to the vehicle so as to minimize vibration. The engine shall

have sufficient output power to drive the pump. During normal operating conditions, the

continuous duty horsepower output required by the engine shall not exceed 75 percent of the full

throttle rating of the engine.

3.9.9 Radio interference suppression. The trailer shall be suppressed to limit electromagnetic

radiation in accordance with SAE J551.

3.9.10 Engine control panel. An engine accelerator, and key-operated start/stop switch shall

be installed on a control panel in a weather and waterproof cabinet. Each control shall be

identified as to function. The cabinet shall be furnished with a side hinged door and a spring

loaded latch with a hasp for a 1-inch padlock.

20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |