|

|||

|

Page Title:

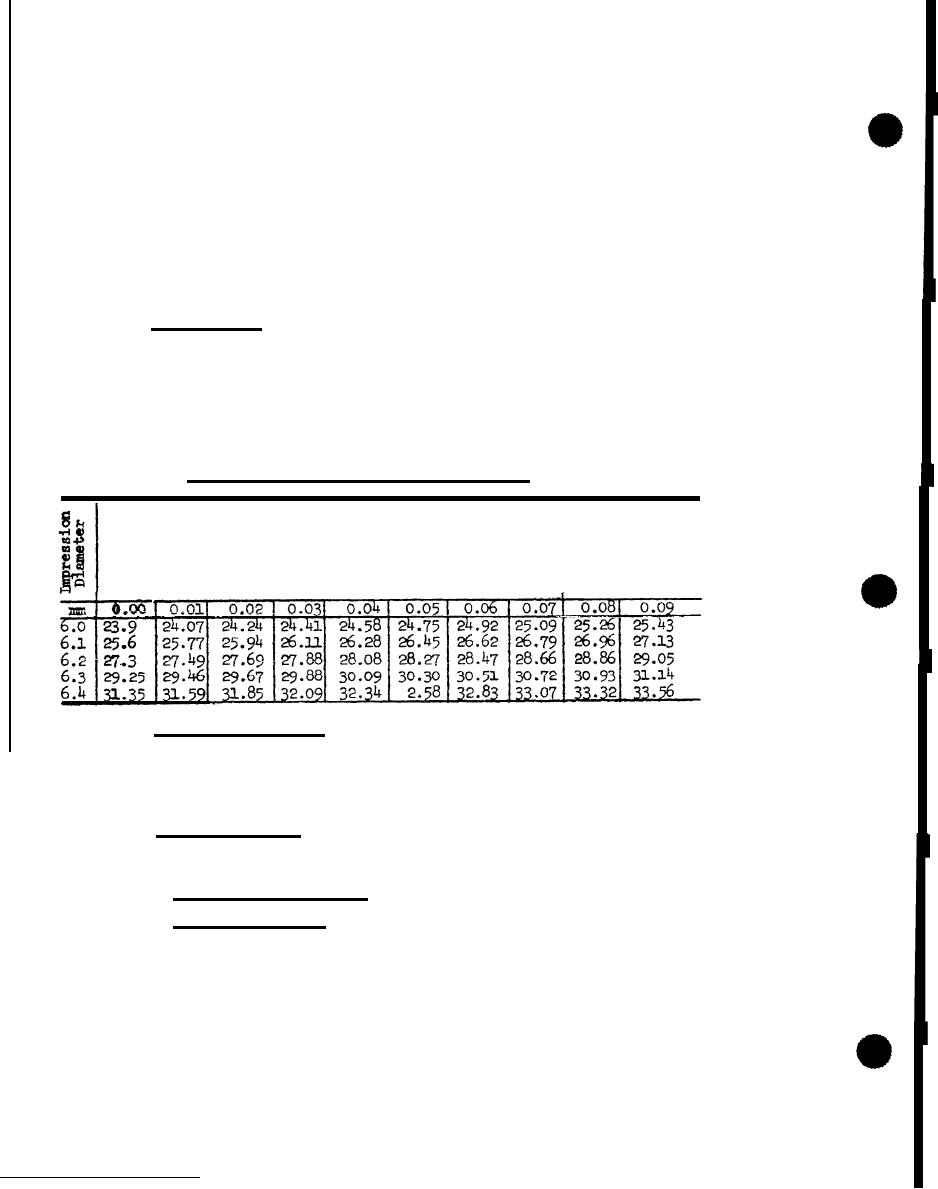

Table I. Force of Blow Conversion Table |

|

||

| ||||||||||

|

|  MIL-T-780E

evidence of damage to the strainer or defective mounting of the strainer;

inability to remove the tamping pad; evidence of excessive wear of the

piston diameter or cylinder diameter (see 3.1.1 and 4.6.2); or absence of

oil vapor in the exhaust air shall constitute failure of this test.

4.5.2.2 Force of blow. Attach a steel ball with a Brinell hardness of

not less than 200 and a (0.499- to 0.500(inch spherical diameter to the end

of the tamper piston rod. With the tamper operating at 90 psig air pressure,

make 20 impressions with the steel ball in a l/4-inch-thick strip of 1020

steel which has a Brinell hardness between 163 and 179. Measure in milli-

meters the mean diameter of the impressions. convert to foot-pounds using

Table I. A force of blow less than 26 foot-pounds shall constitute failure

of this test.

Table I. Force of Blow Conversion Table

Force of Blow - Ft-Lb

4.6.2.3 Air-consumption test. Measure the toted air consumption (cfm of

free air) at 90 psig with the throttle valve fully open. A water displace-

ment meter or airflow meter shall be used in accordance with procedures out-

lined in the Compressed Air and Gas Handbook to determine air consumption.

Air consumption exceeding 46 cfm shall constitute failure of this test.

4.6.2.4 Piston speed test. Determine the piston speed when operating

without butt (blow per minute at no load). Less than that specified in

3.1.1 shall constitute failure of this test.

Sound level measurement.

4.6.2.5

4.6.2.5.1 Operator's station. Measure the sound level at the operator's

I

station, the location above the tamper on its major axis, in accordance with

ANSI 35.1-1971 while operating at 6 bar gage. Nonconformance to 3.5 shall

constitute failure of this test.

8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |