|

|||

|

Page Title:

Resistance to acidified copper-sulfate solution |

|

||

| ||||||||||

|

|  MILT8504B

3.3 Performance

3.3.1 Flarability. Tubing 0.125 inch outside diameter, and over, shall flare to the

respective dimensions of MS33584, when tested as specified in 4.3.6. The flared zones

shall be uniform and smooth, and capable of forming pressuretight joints with standard

fittings.

3.3.2 Flattening. Tubing shall not develop cracks, tears, or other flaws when subjected

to the flattening test specified in 4.3.7.

3.3.3 Bending. Tubing shall not develop cracks tears, breaks, or other flaws when

subjected to the bending test specified in 4.3.8.

3.4 Corrosion resistance

3.4.1 Resistance to acidified coppersulfate solution. The tubing shall exhibit no

evidence of cracks due to intergranular attack when subjected to the examination after

exposure to boiling acidified coppersulfate solution at the conditions specified in

method E of ASTM A 262 and 4.3.9.

3.4.2 Passivation treatment. Treatment of inner and outer surfaces by other than

picking shall be followed by a passivation treatment in accordance with QQP35. The

surfaces shall be passive to tests as specified in 4.3.10.

3.5 Surface conditions. Surface shall be smooth, have a grey metallic appearance and

be free from surface films, scale, flakes, or loose or adherent particles of foreign matter.

All chemical bath residues shall have been removed by rinsing in flowing water,

followed by thorough drying. Compliance shall be determined as specified in 4.3.2.3.

3.5.1 Surface roughness. Surface roughness shall not exceed an arithmetical average

roughness height rating (RHR) of 70 on inside surfaces or RHR 40 on outside surfaces,

as defined by ANSI B 46.1. The maximum depth of individual surface discontinuities

shall not exceed the limits of table III.

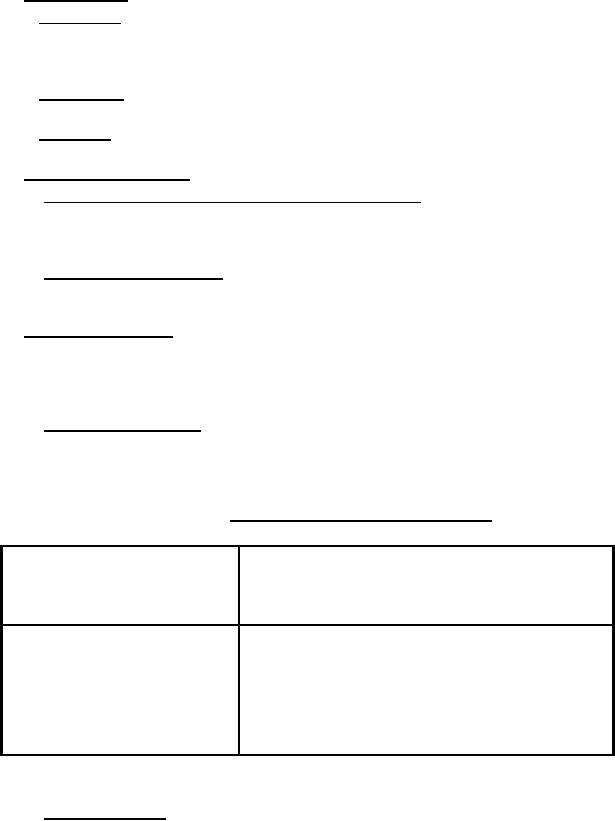

TABLE III. Limits of depth of discontinuities.

Nominal wall thickness

Maximum permissible depth of

(inch)

discontinuities

(inch)

0.020 and under

10 percent of nominal wall thickness

0.021 through 0.030

0.002

0.031 through 0.040

0.0025

0.041 through 0.050

0.003

0.051 through 0.066

0.004

0.067 through 0.085

0.006

3.5.2 Discontinuities. Discontinuities of equal or less depth in the outer surfaces of

tubes shall be removed by light belt polishing or buffing; except that discontinuities

having large root radii plainly visible to the unaided eye, whose surfaces blend smoothly

into the normal tube surface, need not be removed. Passivation treatment shall follow

any surface polishing or buffing operation.

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |